Mechanical Evaporation

Mechanical evaporation is a process that uses mechanical energy to remove water from a solution. This can be done by using a centrifuge, which spins the solution at high speeds to force the water out, or by using a vacuum, which removes the air from the solution, causing the water to evaporate. Mechanical evaporation is often used to concentrate solutions, such as salt water, that would otherwise take a long time to evaporate naturally. It can also be used to remove impurities from solutions, as the impurities are left behind when the water is removed. Mechanical evaporation is a quick and efficient way to remove water from solutions, and it can be used in a variety of industries, such as food and beverage production, pharmaceuticals, and chemical manufacturing.

Minetek's mechanical evaporators are uniquely designed to process a vast range of varying water qualities. The design of the evaporator is based on fan engineering and airflow principles and it was created specifically to evaporate wastewater in an efficient, cost-effective and sustainable way.

One of the key advantages of our evaporation units is the ability to evaporate water with a pH level ranging from 2.2 to 12. This includes acid water, caustic water, high TDS and TSS water. Depending on your climate, our systems have the potential to evaporate up to 50% of spray volume as pure water vapour, with the remaining volume of non-evaporated droplets returning to the feed or tailings pond. Minetek's Model 600/300 Evaporator can process up to 2,250 litres per minute, equating to 135,000 litres per day, resulting in 3,240,000 litres of wastewater processed over 24 hours. Assuming an average evaporation efficiency of 50%, Minetek's Model 600/300 can evaporate up to 1,620,000 litres of wastewater per day. Consequently, using a Minetek water evaporator could be an extremely effective way of managing wastewater while also being cost and environmentally friendly.

Our patented nozzles are specifically designed and engineered to process solids of up to 4.0mm in diameter. This unique design is a critical factor in longevity, durability, and ultimately, the performance of the units. With over 300 projects completed across the globe, Minetek has built a name by delivering the world’s largest and most cost-effective water evaporator system. Offering both land-based and floating evaporation solutions.

Mechanical Evaporation

This technology allows for the environmentally friendly disposal of large volumes of wastewater generated from various industries. Moreover, it does so without the release of any pollutants into the atmosphere. The system works by first separating the wastewater into two streams: one containing suspended solids and the other containing dissolved solids. The stream containing suspended solids is then processed through our patented nozzle array. This breaks down the solids into smaller particles that are then easily evaporated. The stream containing dissolved solids is then passed through a series of filters that remove impurities before it is also evaporated. The result is clean water vapour that is discharged into the atmosphere, leaving behind only a small amount of residue.

This innovative technology has revolutionized the way industries deal with their wastewater, and with over 300 systems installed worldwide, Minetek Water is leading the way in sustainable wastewater management solutions. If you are looking for an effective and environmentally friendly way to dispose of your wastewater.

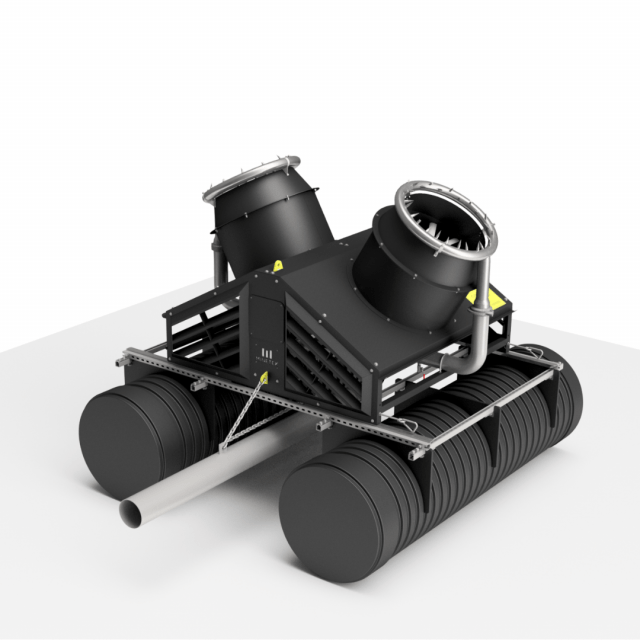

Floating Mechanical Evaporators

Floating evaporators perform even during high winds, returning the remaining volume of droplets to the feed pond. See the product details below;

- Twin 100/50 Evaporators Back-to-Back

- Heavy Duty Construction

- 6 L/sec (95 GPM) Per Unit, Total Flow Rate of 12 L/Sec (190 GPM)

- 7.5kW (10 HP) Motor Per Unit, Total of 15kw (20 HP)

- 18.5kW (25 HP) Submersible Pump to Provide Total 12L/s @ 10 bar (145 PSI)

- Heavy Duty Pontoon Structure with Floats & Pipework

Land Based Mechanical Evaporators

For larger evaporator ponds, land-based evaporators are positioned around the impoundment. See the product details below;

- 37kw - 90kw (15HP-120HP) Electric Motor

- 45m 3 /hour -135m 3 /hour (200-600 GPM) Water Flow Rate

- 10 bar (145 PSI) Pressure Requirement

- Stainless Steel Wetted Parts

- Globally Patented Technology

- Mobile Skid Mounted Unit

- Heavy-Duty Construction Options: Hot dipped Galvanised Steel, Epoxy Coated Steel & 316 Stainless Steel

FAQ - Are the systems operationally capable in extreme climates?

Minetek has evaporators operating in all climates globally including in a very diverse range of operating conditions.

- High humid and tropical climates such as: The Caribbean, Brazil, Central & West Africa, Northern Australia, South Eastern USA

- Cold, seasonal northern climates such as: Alaska, Siberia, British Columbia, Nunavut, Alberta, Saskatchewan, Montana, Illinois, Utah, Nevada, Portugal; Turkey, Azerbaijan, Peru

- Arid & desert climates such as: Australia; South Africa, Mali, Mauritania, Niger, Arizona, California

FAQ - What quality of water are the systems built to operate in?

The Minetek Evaporator is uniquely designed to be able to process a vast range of varying water qualities. We currently have units operating around the world that are evaporating:

- Water ranging from pH 1.0 to pH 14+.

- Acid water.

- Caustic water.

- Water with high Total Dissolved Solids (TDS).

- Water with high Total Suspended Solids (TSS).

FAQ - What amount of solids can the system process?

Up to approximately 150,000ppm 15% solids to suit any water quality.

FAQ - What is the intensity of maintenance required?

Depending on the water quality, a few hours per month.

FAQ - How do you manage drift/over spray?

The Environmental management system (EMS) The EMS stops and starts the evaporation system based on parameters set by the client including weather conditions such as rainfall, temperature, wind speed & direction.

FAQ - How does the weather station work?

The weather station can be operated via the PLC or remotely from your computer. The station can be set to control humidity, rain, wind speed, drift radius, wind direction and to set time periods of operation.

FAQ - How far is the water plume shot into the air?

20 metres up, 15 metres across. This ensures an adequate plume and water particle hang time, with no accumulation of droplets preventing premature fall.

Is regulatory approval/permitting required?

There is typically no governmental precedent regulating the application of this technology. We are essentially taking a naturally occurring process and mechanically enhancing it through the use of the evaporator fans. Minetek is able to assist our clients through this process if required.

Can the system be customised from site to site?

Yes. Options available can take into account:

- Voltage requirements Materials of construction options such as hot dipped galvanized steel, stainless steel and specialized epoxy coatings

- Fixed or adjustable vertical and horizontal discharge angles

- Maintenance safety platforms with handrails (fixed units only)

- Acoustic package

- Automated weather control system

- Suggested spare parts list

FAQ - Can Minetek offer a turnkey solution, including install and commissioning?

Yes. Minetek offer a total turnkey package solution for customers who prefer to have the entire project, designed, engineered and managed from start to finish. This includes an initial site assessment, through to a fully energized and automated evaporation system. Minetek is also able to provide commissioning & training.

FAQ - Are final design and engineering drawings included?

Yes, a full package is supplied including operation & maintenance documentation.

FAQ - Can additional units be added?

Yes. The units are modular and additional units can be added for future requirements.

FAQ - What solutions can Minetek offer for recommissioning of closed mines?

If excess water is an issue or if the pits or underground workings, storage or tailings dams are full of water and are impeding the operation to start up again, Minetek offer a solution through water evaporation. The system can be mobilized quickly and expanded as required.

FAQ - What solutions can Minetek offer for remediation of closed mines?

Excess water is managed in the same way as recommissioning of closed mines, though closed mines includes de-watering and controlling the levels in redundant voids or pits. The application of the Minetek evaporation system also includes the de-watering tailings dams in preparation for capping and closure, and acid mine drainage evaporation. There is also the contingency to quickly mobilize the system in the case of a large weather event and there is risk of overflow. The units can be mobilized and started quickly to draw down dam, pond or pit.

FAQ - Can Minetek offer anything that lowers the environmental footprint?

Yes. Minetek offers a solution that removes the need to discharge water into the environment, or rivers, creeks and streams. If water is evaporated at the source the risk of outside environmental contamination is eliminated. Addressing the problem at the source lowers the risk of pollution to the waterways and ecosystems.

FAQ - Is this a version of a sprinkler irrigation system?

The best possible evaporative result from an irrigation system is 11%. On average, the Minetek evaporation system results in an average of 50%. A sprinkler simply deposits water and replenishes the ground it is not designed to be a mechanical evaporator.

Technical Enquiry

x

Sales Enquiry

x

Kipoi have successfully utilized MINETEK WATER evaporators on our process water pond to remove mine water and has contributed to help with our water balance. We are currently in the process of moving these units to where the catchment area is larger giving us better utilization of the evaporators.

After investigating a raft of different methods from sprinkler systems through to desalination systems (too costly for little benefit) we decided on the MINETEK WATER units. The evaporators were easy to install and once activated ran trouble free. We were very happy with the service from MINETEK and the reliability of the system.

The ability to deliver equipment on time has been a feature of our dealing and we haven't had a situation where a variation has been requested. The quality of their workmanship has been good and the capability of hardware has been as expected or better than quoted”

Our evaporators are still performing flawlessly and working absolutely great. They have been running 24/7 without a single hiccup. Thanks again!

I can honestly say I have found MINTEK WATER a very professional organisation in all the dealings that I have had with them. They have always been proactive and looked for and suggested alternatives to assist me in the delivery of my projects whilst still working on the original concept.