CONTROLLED ENVIRONMENT TESTING

EXPLORING THE MOST CHALLENGING SOUND SCENARIOS.

Minetek has developed extensive in-house testing capability to test and analyse sound and sound behaviour in a controlled environment.

Technical Enquiry

x

Sales Enquiry

x

Our Capabilities

Sound Visualisation

Mobile Fleet Screen Testing

Sound Power Testing

Sound Intensity Testing

Operator Noise Exposure Testing

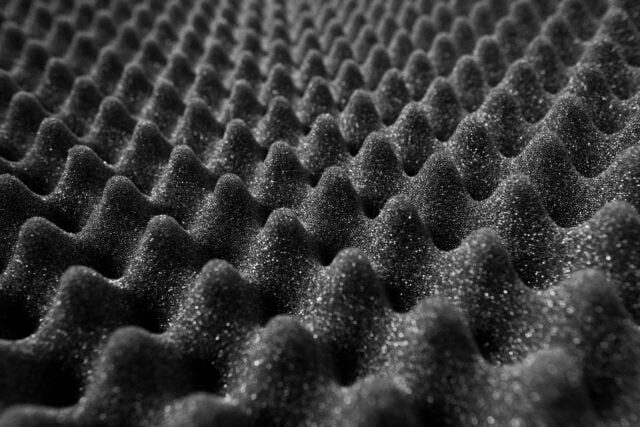

Acoustic Test Chamber

Good product with great service leads to a great outcome. My dealings with MINETEK WATER and their supply and service of evaporator fans was one of high quality. I installed 10 evaporator fans on climate control to maximise efficiency and the results were incredible. From the first meeting through to commissioning nothing was a problem for the MINETEK WATER team. I would highly recommend this product to anyone with water disposal issues.

We have placed some difficult demands upon MINETEK. These demands are never an issue, and are met with the enthusiasm and professionalism we have grown to expect from the MINETEK team.

Our evaporators are still performing flawlessly and working absolutely great. They have been running 24/7 without a single hiccup. Thanks again!

We found the MINETEK WATER team listened and supported our situation with helpful guidance and advice to layout the evaporator pipework maximising their efficiency. I would highly recommend the units to others needing a cost effective solution to excess water.”

The relatively small fans allowed us to utilise our existing bulkhead, where we were severely limited by space, which allowed us to use our existing infrastructure and dramatically reduce downtime in the mine during the change out. The installation was completed safely... and allows us to scale our ventilation flow with their pressure on demand system to suit our production profile.