Since ancient times, the pursuit of extracting precious metals and minerals has driven miners to explore greater depths and risk their lives. From cave-ins, explosions, extreme temperatures, and high humidity to airborne dust and toxic gases, the underground environment poses significant risks to the health and safety of workers.

The modern mine site continues to undergo a drastic transformation as it embraces connected, automated, and innovative technology designed to improve safety, enhance operational efficiencies, maximise productivity and profitability, and secure long-term asset viability.

Despite the challenges and risks at stake, the demand for safe, reliable and efficient air supply underground remains a top priority in protecting miners. Like silica dust in construction and stone manufacturing, other lung diseases attributed to working below ground have forced mine operators to address air quality issues by adopting technology that mitigates these risks.

This is where underground ventilation systems play a critical role in controlling air quality by diluting and removing contaminants such as dust, diesel fumes, heat and toxic gases while regulating temperature and humidity levels.

Underground airflow & ventilation systems

Ventilation systems can also contribute to lowering a mine’s power consumption and emissions output by 30-50 per cent by switching to green electricity sources. Therefore, it’s no surprise the push toward achieving net-zero emissions targets and efforts to decarbonise and remain ESG compliant is driving asset owners to search for smarter ways to optimise airflow underground.

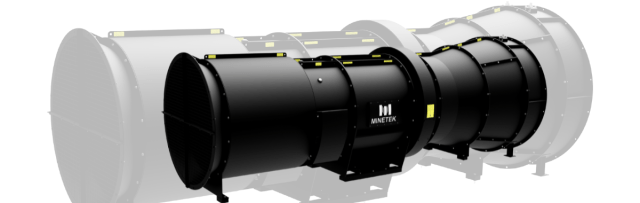

As pioneers in air ventilation, water management, sound attenuation, power supply and distribution, global industrial mining solutions provider Minetek has been known for introducing game-changing technology to the industry for over 30 years.

Having successfully delivered over 3,000 projects worldwide, the company’s air ventilation division Minetek Air is now synonymous with sophisticated modular air management solutions for underground mines that deliver the required airflow to all working areas at the lowest cost.

Engineered fans with mining in mind.

Embracing agile ventilation technology assists operators in limiting airflow in parts of a mine with no scheduled activity, which reduces their energy consumption exponentially. Regarding world-class engineering, breakthrough technology, and intensive research and development, Minetek’s underground ventilation systems are the complete package.

It’s Primary Ventilation and Booster Fans are no exception. Primary (or main fans) are installed on the surface or below ground level in a bulkhead application and direct air into and out of a mine while removing contaminants in the process.

According to Minetek Air underground mining ventilation manager Jeremy Sutherland, the importance of selecting the right ventilation system in an underground mine can’t be overstated.

“Our ventilation fans were engineered to safely increase productivity, deliver cost savings, durability and flexibility not achieved with traditional fans,” said Mr Sutherland.

“Minetek’s primary fans suck air through a mine at 150 cubic metres per second, with the aim of replacing the air every 20-40 minutes. In larger or deeper mines, these fans can move between 450-900 cubic metres of air per second through their main decline with the support of booster fans or additional single return airways.

“Installing a booster fan in conjunction with the primary fan at the mine’s surface, helps increase air pressure of the ventilation passing through the air ducts, which can reduce pressure from the primary fan and provide the air pressures needed for deep underground mining operations.”

Secondary ventilation fans.

Minetek’s Secondary (auxiliary) ventilation fans have also become a ‘fan favourite’ for mining operations wanting to effectively regulate airflow at greater depths. These secondary fans are used to supplement the primary ventilation system, particularly in deeper mines where airflow is stagnant.

Secondary fans essentially provide ventilation to development ends, stopes and services facilities that constitute secondary circuits tapped off the primary circuit or main through the flow of air.

Mr Sutherland says Minetek’s secondary fans are like no other on the market.

“They’re compact in size, 40 percent shorter and 10 percent lighter than standard fans, while the high-pressure capability of our high output axial fan is double that of standard fans comparable in size. This reduces the number of fans required, therefore minimising costs over the long-term, with low-profile ducting that makes installation more streamlined than other fans available.”

Minetek’s High Output Axial Fans incorporate a robust steel fabricated impeller designed for prolonged life and operation at pressures previously thought impossible, even in the harshest underground environments.

The concentrated power of these axial fans make them ideal for long duct-runs when operators need additional pressure to maintain airflow up to 1,500 metres, while minimising air volume loss across the vent line network. The fans can also surge past the required duty point to clear gases and dust for fast re-entry, increasing production and reducing capital costs over the mine’s lifecycle.

Sustainable fan performance & airflow on demand.

It’s suggested that underground ventilation contributes 42-49% of a typical mine’s energy cost. With an increased focus on energy efficiency and ESG credentials, new innovations in ventilation technology are redefining how mining companies boost operational efficiencies and minimise power consumption.

Mr Sutherland highlighted that Minetek’s powerful single-speed primary and secondary fans had been proven to reduce power consumption costs by up to 50 per cent and improve underground mining ventilation systems.

“Compared to larger fans, our compact units outperform larger alternatives and can be re-deployed quickly and easily to other locations as mine operations evolve,” he said.

“The flexible airflow using our Performance On Demand (POD) system can ramp up or down, accommodating changes in mine activity, and only using as much power as required. This technology allows operators to tailor pressure and power consumption through our potentiometer without the need for Variable Speed Drive (VSD) controls.

“Our impulse-bladed impeller controls the POD system with anti-stall technology, which captures turbulent airflow and unstable pre-swirls to ensure optimal fan performance and prevent critical fan stalls.”

With the ability to integrate with all mining Ventilation On Demand (VOD) and mine communication systems, mines can benefit from lower power consumption costs and greater operational efficiencies.

When coupled with its Mine Air Control (MAC) system, Minetek fans provide a seamless, responsive solution that synchronises the entire ventilation circuit, allowing airflow from the fan to be controlled from the surface based on scheduling and vehicle movements identified using RFID trackers.

For more information on Minetek’s underground ventilation solutions, leave your details below.