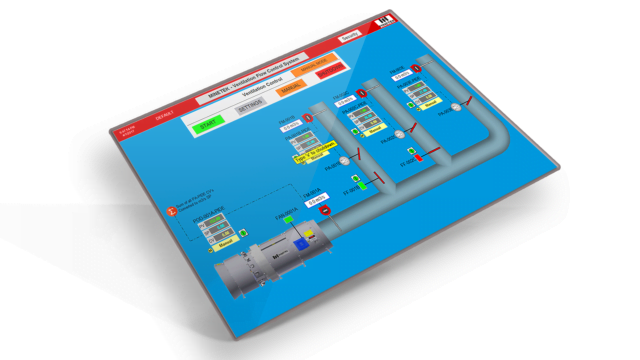

MINE AIR CONTROL (MAC) SYSTEM

Minetek's mine air control (MAC) system seamlessly integrated with the operating layer of the mine to optimise airflow across the entire air circuit. With the ability to ramp airflow up and down based on scheduling and vehicle movements identified by using RFID trackers. Our mine ventilation control system enables seamless operation with the ability to control from above the mine's surface.

REDUCE DOWNTIME & ACHIEVE OPERATIONAL EFFICENCY

Linking directly to the Performance on Demand (POD) systems on the Minetek fan range, it automatically ramps the airflow up or down as required. Air quality control for mining is required on some mines as a condition of their development approval and/or environment protection licenses issued by the EPA. These conditions require mining operators to monitor, manage and report on air pollutant levels in and around their mines.

The computerised controller allows for the management of airflow, from low flow during low activity times, right through to more than double the duty point of a traditional vane axial fan. This capacity to control high-pressure ventilation from the surface gives the ability to quickly blast gases or dust out for faster and safer re-entry times.

The automated monitoring and adapting of ventilation creates an all-around safer environment, as there’s no chance of human error and underestimating the correct amount of airflow needed. Minetek’s smart system will save any site money, with a guaranteed return on investment.

Save on power, additional fan installs and delayed re-entry with Minetek’s Mine Air Control patented system. Talk to Minetek about air quality control for mining today.

MULTIPLE HEADING DEVELOPMENTS

Limit the amount of fans required throughout multiple heading developments with Minetek.

As with our other applications, the high output, steel impeller design gives over double the duty point of traditional fans of the same comparable size. Quiet, efficient, with smart technology and streamlined features.

Low fan profile, single duct runs and minimal installs needed throughout the project are all advantages of using Minetek solutions.

EXPLORE OUR TECHNOLOGY

Minetek provide innovative, customised solutions for sites all across the world. With the first steel impeller design, Power on Demand (POD) smart feature, and streamlined engineering, our fans are smaller, stronger and smarter.

Technical Enquiry

x

Sales Enquiry

x

Our Capabilities

Primary Ventilation Fans

Secondary Auxiliary Fans

Booster Fans

Multiple Heading Ventilation

Bulkhead Fans

Long Duct Runs

Tunnel Fans

Development Fans

Mine Air Control (Mac)

We are always looking at new innovations and technologies that will benefit both us and our clients. Minetek has been able to display that with the use of their modern ventilation technology, where we can look to see production increases through faster re-entry times and reduced capital costs in the total life of the development, delivering value to both us and Mincor.

MINETEK will continue to be a favoured technical resource and supplier to the New Hope Group and are recommended as a professional, respected and competent supplier of technical services, equipment and products for noise abatement and other industrial products.

Good product with great service leads to a great outcome. My dealings with MINETEK WATER and their supply and service of evaporator fans was one of high quality. I installed 10 evaporator fans on climate control to maximise efficiency and the results were incredible. From the first meeting through to commissioning nothing was a problem for the MINETEK WATER team. I would highly recommend this product to anyone with water disposal issues.

I can honestly say I have found MINTEK WATER a very professional organisation in all the dealings that I have had with them. They have always been proactive and looked for and suggested alternatives to assist me in the delivery of my projects whilst still working on the original concept.

MINETEK provides quality, proven solutions and are established as leading air attenuation specialists.