According to an analysis by scientists from NOAA’s National Centers for Environmental Information (NCEI), last year was one of the warmest on record, with 2022 ranked among the sixth-warmest year on record since 1880 [1]. Throughout the Northern Hemisphere, surface temperatures were among the sixth-highest recorded since 1878, when such records began. Rising temperatures and seasonal changes bring risks and challenges to the mining, industrial, oil and gas, power generation and other industries.

Freshets start to occur when the temperatures heat up and the spring thaw sets in, leading to snow and ice melts. This results in excess groundwater which can impact day-to-day operations and prevent ongoing production. When combined with heavy rainfall or extreme snow dumps, the impact of freshets can be more extreme, potentially impacting onsite infrastructure, roads, Tailings Storage Facilities (TSF) and waste areas. As a result, infrastructure may fail which can lead to significant environmental and safety impacts.

The impacts of freshet snowmelts on mine sites.

The time between early summer and spring is particularly conflicting for industrial operators and the mining industry. As snow and ice start to melt, freshets occur, bringing unfavourable conditions for ongoing production. Snowmelt runoff from a change in temperature can have damaging consequences on mining operations, causing flooding and waterlogging to open pit mines. This dangerous situation poses risks to both equipment and personnel but, more importantly, hinders progress and production. Mining and industrial operators must shift their focus away from production and towards emergency water management tasks. A temporary shutdown of mining operations may be imminent without an effective mitigation water management strategy in place.

Sibanye-Stillwater’s uranium and gold mines in Montana have been an economic force for years, however, last year, they recently faced a devastating flood event [3]. On-site flooding was triggered by the warm weather with freshets forming due to rapid snow and ice melts. This was further intensified by excessive rainfall, which exacerbated the situation and created substantial damage. Significant repair and recovery efforts were required to bring operations back up to full capacity. This resulted in the suspension of operations, as the scale of the flooding was so severe that several months later, revenue losses were strongly felt.

Minto Gold Mine in Yukon Canada experienced a challenging second quarter of 2022 due to flooding from freshets and excess water from snow and ice melts [5]. Snowfall in the region was 150% – 400% higher than normal, with freshets causing operations to be suspended for four and a half weeks costing the company millions [6]. Over a three-month period, Minto Mine recorded a record loss of $9.5 million CAD, adjusting the EBITDA from a profit of $8.72 million CAD to a loss of $941,000 CAD [5].

What North American regions are affected by freshets and snowmelts?

The mining, oil and gas, industrial and energy industries in northern climates such as Canada and America need to be prepared and well-equipped for the unique challenges posed by snowmelts. As spring freshets and snow accumulated within the tailing’s footprint area begin to melt, the resultant water must either be discharged or contained within the TSF. During these short and intense periods, the daily water inflow exceeds the discharge capacity of a mine, leading to the rise of water levels in TSF’s.

TSF’s and water storage facilities are pushed to their limits during spring and impoundment areas may reach the maximum allowable water level. Without a full-fledged water management plan and risk mitigation strategy operations may be forced to temporarily halt production. This puts increased pressure on TSF levels which can pose risks such as dam failure if water levels are to exceed capacity limits. This may result in the release of toxic acid water into surrounding areas causing permanent environmental damage due.

North American regions impacted by freshets and snowmelts.

Canada.

- British Colombia

- Yukon

- Alberta

- Saskatchewan

- Manitoba

- Ontario

- Quebec

- Nova Scotia

- Northwest Territories

- Nunavut

- Newfoundland

- Labrador

USA

- Nevada

- Idaho

- Utah

- Colorado

- Alaska

- Wyoming

- Montana

- Washington State

- North Dakota

- South Dakota

- Minnesota

- Wisconsin

- Michigan

- Ohio

- Kentucky

- Tennessee

- Missouri

- West Virginia

How can mine sites in North America prepare for freshet snowmelts?

Mining, oil and gas and industrial sites across Canada and the United States can prepare for freshet springs and increased water inflow by implementing an effective water management plan and vigilant monitoring of changes in environmental conditions [6]. Emergency and contingency planning must be finalised for rapid implementation when required. Mines in high-risk locations need to assess their water management plans regularly personnel must be aware of the roles and responsibilities they have, and available resources required to implement an emergency response plan for freshet snow melts.

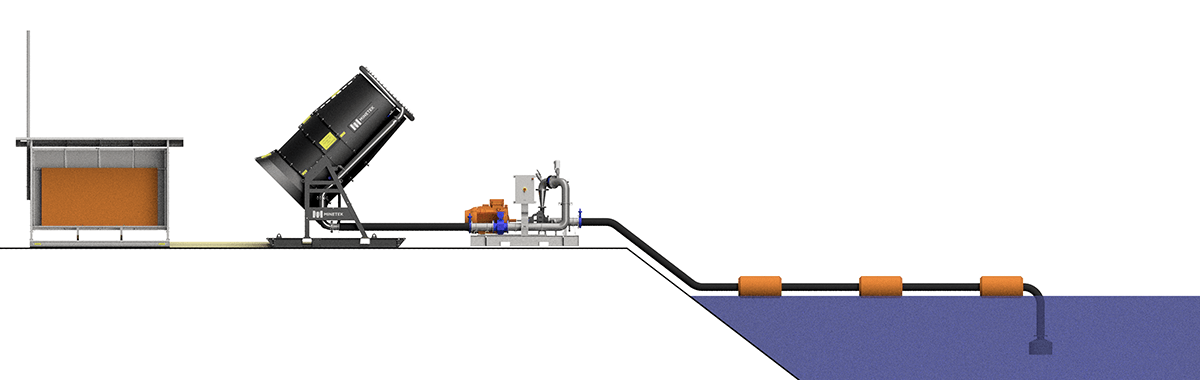

Operations situated in high snowfall areas are constantly searching for more efficient and effective ways to mitigate the safety, environmental, and commercial risks of freshet snow and ice melts. The implementation of a water evaporation system is a particularly promising solution, designed to remove excess water, reduce dam water levels, and ensure compliance with global standards. Minetek provides a comprehensive solution with a specialised evaporation system that offers cost-effective solutions for mine operations across North America.

Water evaporation technology.

Minetek’s innovative water evaporator technology embodies advanced fan engineering and airflow principles. These units are specifically engineered and designed to evaporate wastewater efficiently, cost-effectively, and sustainably. Our Evaporators can evaporate water ranging from pH 2.2 to pH 12; including acid water, caustic water, high TDS and TSS. Minetek’s units can evaporate on average 50% of the volume pumped through the evaporator system. These robust capabilities allow our customers to maximise performance and efficiency when using our equipment. Our patented nozzles are designed and engineered to process large solids up to 4.0mm in diameter, enabling longer life cycles and consistent performance. For mine sites with limited access, we offer floating wastewater evaporators that offer the same capabilities as the land-based system but are situated on a floating pontoon.

Minetek Water has completed over 500 successful projects in 25 countries worldwide. Our floating and land based wastewater evaporation systems are the optimal choice for managing excess water derived from freshets and snow melts. Minetek’s robustly designed units are high-quality products, making us an excellent choice for advanced and reliable water evaporator systems across a variety of applications.

Contact Minetek if you are looking for an effective and environmentally friendly way to dispose of excess water from fresher snowmelts.

Resources

- National Centers for Environmental Information – https://www.ncei.noaa.gov/news/global-climate-202212

- World Mine Tailings Failures – https://worldminetailingsfailures.org/

- Mining Journal – https://www.mining-journal.com/pgms/news/1434114/flooding-hits-sibanye-stillwaters-us-operations

- Scripps Media – https://www.ktvq.com/homepage-showcase/we-have-never-experienced-a-loss-like-this-stillwater-mine-still-dealing-with-impacts-of-june-floods

- Mining Journal – https://www.mining-journal.com/commodities/news/1438297/freshet-takes-spring-out-of-minto%E2%80%99s-step

- Mining Weekly – https://www.miningweekly.com/article/spring-freshet-impacts-on-minto-2022-08-24

- Ministry of Energy, Mines and Low Carbon Innovation – https://www2.gov.bc.ca/assets/gov/farming-natural-resources-and-industry/mineral-exploration-mining/documents/health-and-safety/health__safety_notice_freshet_2022_1.pdf