Mining in Western Australia has long been one of the state’s most crucial industries, but it has grown to historic proportions in recent years, contributing over $100 billion to the economy and supporting more local jobs than ever [1]. According to a DMIRS report, since 1997-98, the number of miners working in the mining sector has tripled from 43,466 to 132,144 from 2019-2020 [2].

While this impressive growth continues to power Western Australia’s (WA) economy forward, it brings a greater risk of Lost-Time Injuries (LTIs). In response to the growing sector, the Australian government has recently passed new legislation requiring mine sites to assess risks and develop controls to mitigate them. This is essential to ensuring WA’s miners stay safe and compliant with all mine safety and inspection regulations.

Western Australia’s Work, Health, and Safety Regulations 2022 (WHS Regulations) came into full effect on 31 March 2022, granting the Mining Industry of Western Australia a great deal of needed protection. The introduction of this new system would bring the Work, Health, and Safety Act 2020 into full force, accompanied by several subsidiary regulations specific to industries such as Petroleum and Geothermal Energy Operations and Mines [3]. These regulations provide an improved framework to ensure employers fulfil their obligations and create safer workplaces for both employees and visitors.

Work health and safety mine regulations 2022 update

The WHS Act introduced a new primary WHS duty for a ‘person conducting a business or undertaking’ (PCBU) to ensure, so far as possible, the health and safety of workers and other personnel arising from the conduct of their business or undertaking [3]. The duty requires a PCBU to eliminate risks to health and safety so far as is reasonably practicable and, where it is not, minimise identified risks as much as possible. What is considered ‘reasonably practicable’ will depend on several considerations, including the likelihood of a hazard or risk occurring, the degree of harm that might result from the hazard or danger, and the availability and suitability of ways to eliminate or minimise identified risks.

Another critical change is that penalties for breaching health and safety regulations have significantly increased. Not only is there now an offence of industrial manslaughter, which carries heavy penalties if a breach causes serious harm or, worse, death, but the WHS Act also voids the option of purchasing insurance to cover these penalties.

In relation to mines, a key component of the new regulation is the extensive set of guidelines that dictate a hierarchy of control measures involving specific steps implemented in a specified order. Broadly speaking, employers are required to guarantee the safety of their working environment for miners and other personnel by providing safe facilities, systems, information, training, and instruction needed to protect workers from health and safety risks.

What impact will these regulations have on the mining industry in Western Australia?

Mine operators are under significant regulations to avoid dangerous, high-risk mining activity. Notably, they must provide written notification to the regulator 15 days before single entry development beyond 200m from through ventilation is commenced [4]. However, there is an exception to this regulation: applicants are exempted if their details of the high-risk mining activities are already included in either a mining commencement notice or additional operations notice. Mine operators should be aware of these requirements when conducting the required operations and ensure compliance with the regulations enforceable by the respective regulator.

The new regulations apply to all mines beyond 200 metres underground, requiring them to assess risks and develop mitigation controls [5].m [5]. The new rules have also been designed to ensure that mine operators are taking proactive measures when it comes to health and safety instead of simply relying on workers to avoid hazardous areas. It is now mandatory for mines in Western Australia to have controls that can prevent accidents or minimise harm if they occur.

In lieu of the monthly status report forms previously submitted to the department, the new regulations require mining operators to give the regulator a work health and safety report at least once a quarter. The mine operator is responsible for upholding these regulations, allowing for improved safety standards at their mine site.

Before this new legislation came into effect, managers of mining sites faced little accountability. They only had to offer warnings of dangers, such as opening holes, without any form of control in place to protect miners. Western Australian mines must now conduct risk assessments and be equipped with management and control plans that mitigate dangers according to the region’s local government. For the above example, this might include closing the hole, adding ladders, or blocking tunnels. Mining sites must also now have an escape plan with designated ventilation points and additional chambers with clear pathways in the event of an emergency. These measures are all designed to reduce risk and keep miners safe, meaning fewer accidents and more successful practices.

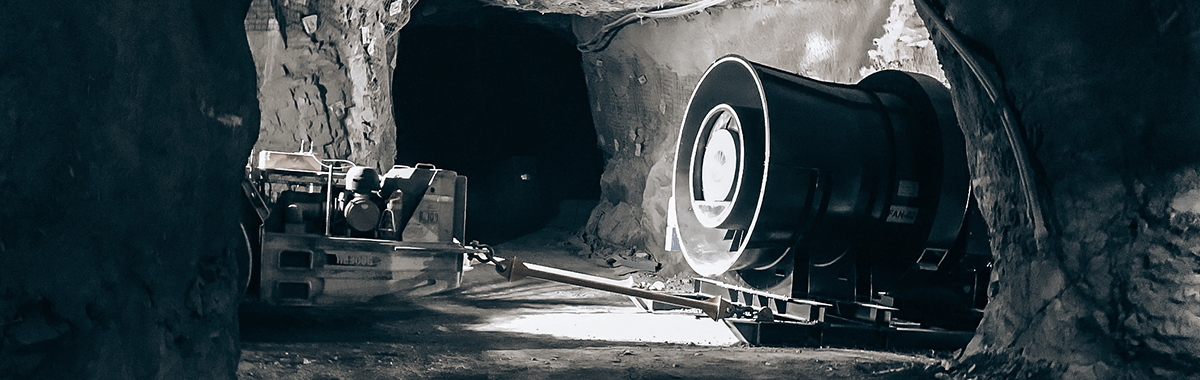

The most notable change brought about by this new legislation is regarding ventilation. Mines must now have a ventilation plan cover the assumption that all their underground fleets could be underground at any time [3]. This means that if a mine usually has five trucks operating, but has twenty available, and the ventilation plan must cater for those extra fifteen, adding considerable cost to the operation. Many mining operations across Western Australia have turned to Mine Air Control (MAC) Systems equipped with RFID trackers to reduce the costs associated with additional vehicles. This technology can automatically detect new vehicles entering a mine and adjust ventilation accordingly. Not only is this system able to provide improved safety measures, but it also offers significant cost savings compared to traditional methods.

Underground ventilation control systems

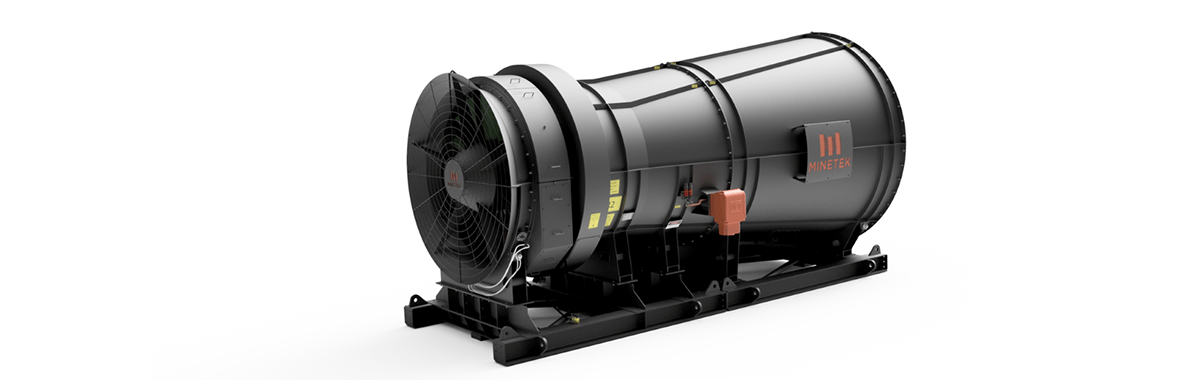

Minetek’s High Output Axial Fan system has been designed completely with the underground mining industry in mind. The Mine Air Control (MAC) system is designed to provide the most efficient ventilation for miners working underground. Minetek’s patented Performance on Demand (POD) technology is an innovative approach to optimising performance and reducing power consumption costs for operators. POD enables operators to tailor pressure and power consumption without having to use VSD (Variable Speed Drive) control, providing a more responsive solution. This simplifies the process of controlling output while also increasing overall operational efficiency.

Our sophisticated computerised control system helps keep operations running smoothly and efficiently by regulating underground airflow. This includes optimisation of low flow during less high-activity times and increasing up to double the duty point of a traditional vane axial fan. Such capacity helps ensure that dangerous gases or dust can be quickly removed from entry sites, thus reducing risks associated with entering such conditions while also eliminating much of the power traditionally wasted in such applications and meeting broad regulatory compliance parameters.

The Minetek High Output Axial Fan system is modular and comes up with additional benefits:

- Vastly reduced energy costs

- Adequate air at the face

- High levels of control

- Large operating range

- Sensor tracking to automatically adjust to real-time demand

- High volume compliance

- Blast dust removal rapidly

- Reduced noise output

With an increased focus on risk assessments and control management across Western Australia, the mining industry must take proactive steps to ensure maximum safety for workers and compliance with stringent regulations. Minetek’s innovative MAC system offers an improved ventilation capacity that surpasses competing systems – helping ensure air quality standards are met while reducing potential costs. The MAC system is ideal for creating safer work sites with improved ventilation capacity while ensuring cost efficiency and meeting regulatory guidelines.

Contact us if you would like to learn more about how we can assist with your underground ventilation solutions.

References

- Department of Mines, Industry Regulation and Safety Western Australia – https://www.dmp.wa.gov.au/About-Us-Careers/Latest-Statistics-Release-4081.aspx

- ABC (Australian Broadcasting Corporation) News – https://www.abc.net.au/news/2021-01-29/wa-mine-workers-seriously-injured-at-rate-of-more-than-one-a-day/13104168

- Western Australia Work Health and Safety Regulations 2022 – https://www.legislation.wa.gov.au/legislation/prod/filestore.nsf/FileURL/mrdoc_44753.pdf/$FILE/Work%20Health%20and%20Safety%20(Mines)%20Regulations%202022%20-%20%5B00-a0-01%5D.pdf

- Government of Western Australia – https://www.wa.gov.au/government/publications/notification-of-high-risk-mining-activity-single-entry-development-beyond-200-metres-through-ventilation