The role of fans in maintaining the air quality and safety of underground mines cannot be overstated. These ventilation systems are indispensable in providing a constant flow of fresh air, preventing the build-up of toxic gases, and protecting workers from respiratory ailments. In addition to their critical role in maintaining air quality, fans also play a vital role in keeping mining equipment cool and operational. Any downtime in production can result in significant financial losses, making optimal fan performance essential.

Selecting the right fan is a crucial decision that demands careful consideration. However, not all fans are created equal, and their performance can vary greatly depending on various factors, such as diameter, speed, and blade pitch angle. This is where the concept of a fan curve comes in, providing an invaluable graphical representation of a fan’s performance and the relationships between its key parameters. By leveraging this information, mining operators can confidently select the right fan, safeguarding worker safety and the mine’s productivity.

What are fan performance curves?

Fan performance curves are a powerful tool that visually represents a fan’s ability to move air at different flow rates and pressures. Understanding these curves is crucial in selecting the most suitable fan for a specific application and operating it with peak efficiency.

Fan performance curves are typically plotted on a graph with volume flowrate and pressure as the two axes. Fan curve families have multiple curves depicted on the one graph, showing how the fan’s airflow and pressure change in response to various operating conditions. Each curve will represent how the fan’s airflow and pressure change in response to various operating conditions, including different diameters, running speeds, densities and impeller configurations.

When selecting a fan, it is paramount to consider both the flow rate and pressure requirements to determine the appropriate operating point where the system’s airflow resistance and the fan’s pressure capabilities intersect. This point indicates the actual flow rate the fan will produce at the given pressure.

Moreover, fan performance curves also aid in troubleshooting and diagnosing problems with the fan’s performance. Tracking the operating point makes it possible to identify issues such as clogged filters, closed dampers, or pressure, leading to a state of stall by exceeding the fan’s design capacity. Correcting these issues ensures efficient fan operation, avoids potential damage to the motor or fan down time.

Fan performance curves are a valuable resource for selecting the most appropriate fan for a given application, optimising its performance, and diagnosing issues that may arise during operation. Engineers and technicians can ensure that fans operate at their best by leveraging the power of fan performance curves, maintaining efficient airflow and pressure to achieve optimal system performance.

Key terminology to know when reading a fan performance curve

Reading a fan performance curve can be challenging, but it is a critical skill for efficiently selecting and operating a fan. Understanding the three primary parameters, namely static pressure (Pa or in.wg), volume flowrate (m3/s or CFM), and power (Kw or BHP), and their relationships is essential in interpreting fan performance curves.

Volume flowrate

Volume flowrate is a metric that measures the fan’s capability to generate air movement at different static pressure levels, which is typically displayed on the x-axis of the fan’s performance curve. In the United States, this is typically quantified in cubic feet per minute (CFM), while the internationally recognized unit of measurement for air volume flow rate is m³/s. The value of a fan is profoundly influenced by the speed at which it operates and the size of its awe-inspiring impeller blades, both of which play crucial roles in its exceptional performance.

Static pressure

Static pressure refers to the resistance that air encounters as it flows through a system, such as a duct or a filter. This pressure is exerted on the walls of the system and is quantified in inch water gage (in.wg). In the context of a fan’s performance, the static pressure (SP) value is typically illustrated on the y-axis of the performance curve. Higher SP values correspond to greater resistance in the system, resulting in lower m³/s values.

Power

Fan power is a crucial metric that quantifies the output of power required to propel a fan to its maximum potential. In the United States, this metric is conventionally measured in brake horsepower (BHP or HP), while kilowatts (kW) are the standard unit of measurement in most other regions such as Canada and Australia. The HP or Kw value reflects the optimal amount of power that the fan requires to achieve its designated speed and performance level.

Operating point and application

The operating point represents the intersection of the volume flowrate and SP values on the performance curve, corresponding to the conditions under which the fan operates. The application of the fan, such as ventilation, cooling, or extraction, determines the required operating point. To select the appropriate fan for an application, it is necessary to identify the operating point and match it with the fan’s performance curve.

What is stall, and why it they occur?

Measuring these different components, such as volume flowrate (CFM), static pressure (SP), and brake horsepower (BHP), can provide critical information for keeping the system running efficiently and preventing costly fan stalls.

Fan stalls occur when the airflow through a fan is disrupted or reduced to the point where the fan blades no longer have enough air to work against. This can be caused by a variety of factors, including changes in the system resistance due to dirty air filters or ductwork, incorrect fan speed settings, or inadequate maintenance.

The consequences of fan stalls can be severe, both in terms of energy efficiency and overall system performance. When a fan stalls the state of performance reduces and may trip on vibration, over temperature or other safeties – leading to the fan stopping, causing a complete loss of ventilation or cooling, which can be detrimental to the health and comfort of occupants in the vicinity. Additionally, when a fan stalls it can cause damage to the fan motor, impeller and bearings, reducing the lifespan of the equipment and leading to costly repairs or replacements.

Measuring the CFM, SP, and BHP of a ventilation system can help identify potential issues before they lead to fan stalls. Monitoring these components regularly makes it possible to detect changes in system performance and take corrective action before they escalate. For example, if the CFM value drops below the expected level, it may indicate a blockage or obstruction in the ductwork that needs to be cleared.

Plotting a fan performance curve

At Minetek, we pride ourselves on our ability to deliver exceptional fan solutions to our mining clients. We achieve this by creating a fan performance curve customised to the specific duty point required by the mine. This involves a meticulous selection process, where we carefully consider the client’s needs and select a fan that meets those needs and provides excellent value.

We offer an extensive range of primary and secondary fans, each with unique specifications and capabilities, ensuring that our clients can find a fan that is perfectly suited to their requirements. Our fan options range from 90kw all the way up to 1,110kw, providing a broad selection of solutions to choose from.

This is an example of a fan performance curve. Minetek, with its pioneering POD technology, boasts an expansive operating range that extends to the far reaches of the red area. Competitor fans, however, are constrained by a meagre operating range. Minetek fans, on the other hand, exhibit unprecedented versatility and can operate at peak performance levels across an extensive range of static pressures and airflows.

Minetek’s fan performance

Primary / Booster Fan range

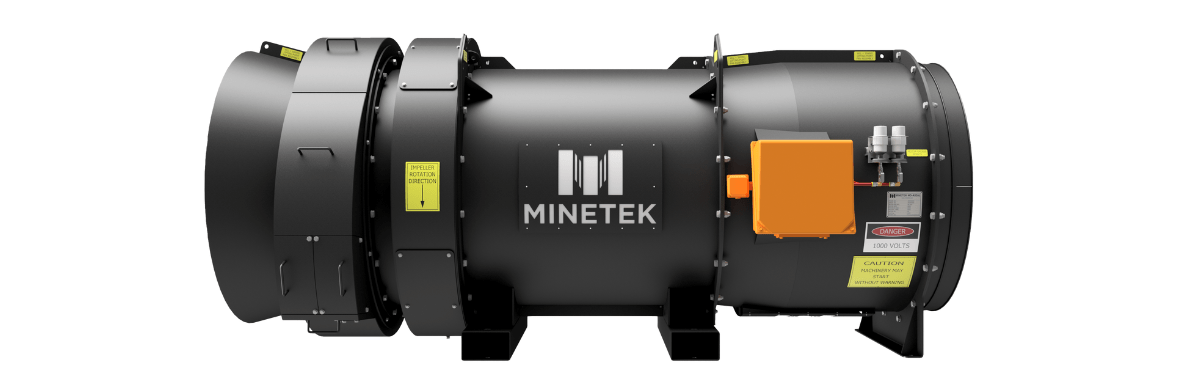

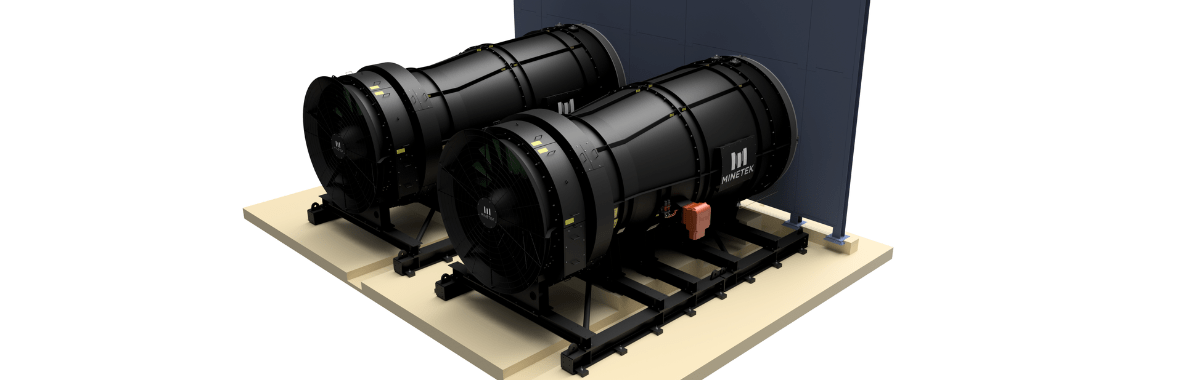

Minetek’s Primary / Booster Fan Range boasts an extraordinary range of exceptionally high-performance fans meticulously designed to cater to the highly specialised needs of underground mining sites.

- Power range 200 – 2,700 HP / 150 – 2,000 kW

- Volume 106,000 – 2,119,000 CFM 50 – 1000 m3/s

- Pressure 200 – 27 in.wg / 200 – 8000 Pa

- Efficiency > 85%

Secondary / Auxiliary Fan range

Minetek’s Secondary/Auxiliary Fan Range presents an extensive array of fans precisely designed to meet the unique and specific demands of underground mine sites.

- Power range 120 – 500 HP / 90 – 375 kW

- Volume 22,120 – 211,900 CFM / 10 – 100 m3/s

- Pressure 0.80 – 27 in.wg / 200 – 6500 Pa

- Efficiency > 85

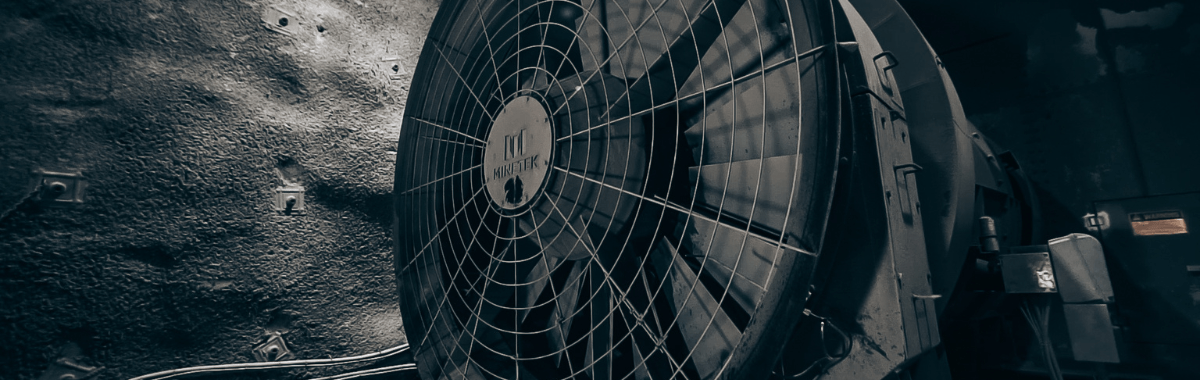

The benefits of Minetek’s High-Output Axial Fan

At Minetek, we strive to deliver cutting-edge ventilation technology through world-class engineering, intensive research and development, and breakthrough technology. Our underground ventilation technology is the pinnacle of innovation, providing unparalleled economic, operational, and safety benefits unmatched anywhere else in the world.

Minetek’s mine ventilation system features underground fans that enhance airflow and eliminates power wastage in underground mining applications. This remarkable system utilises a patented Mine Air Control (MAC) technology that enables the Performance on Demand (POD) units to sense the required airflow in any heading at any given time, maximising their performance. The system’s high-pressure, steel-fabricated impeller technology allows for operation in temperatures, and conditions once thought impossible for an Axial Fan.

The Axial Fan’s key feature is its POD system, which comprises an electronic controller that enables the fan to be regulated from low flow requirements to over double the duty point of a conventional vane axial fan, resulting in significant cost savings. The MAC System RFID trackers play a critical role in its cost-efficiency, continuously monitoring the movement of underground mining equipment and automatically adjusting the air volumetric flow to provide sufficient ventilation for the area and disperse the gases.

Minetek’s revolutionary anti-stall chamber is a feat of engineering, expertly regulating air movement by capturing turbulent airflow and unstable pre-swirls. This ingenious technology eliminates critical stalls and improves the fan’s operating range and overall performance, providing unparalleled outcomes for underground mining sites.

This modular system is custom-engineered and manufactured in Australia to meet the end user’s specific needs, making it a highly reliable and adaptable solution for various underground mining applications.

Contact us today to learn more about our underground ventilation solutions and how we can help you achieve optimal performance.