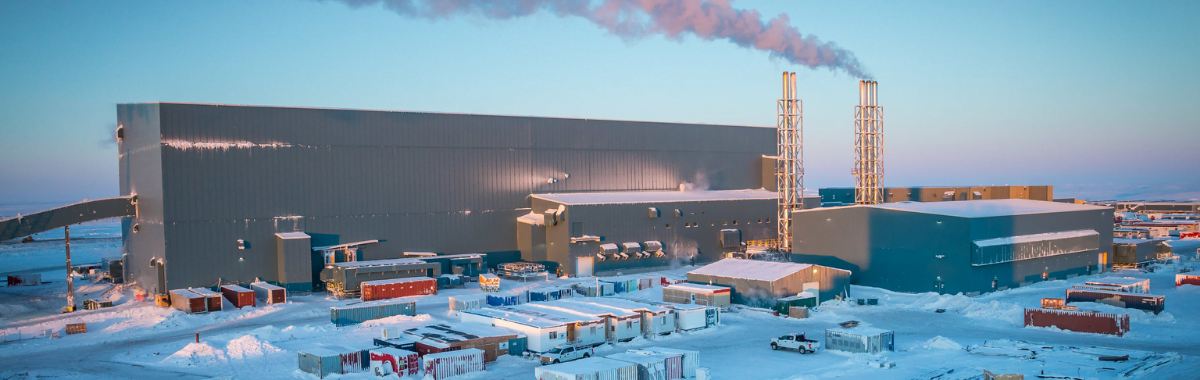

Meliadine Mine is situated within the Kivalliq region, north of Rankin Inlet in Canada. This high-grade gold mine is a long-life producing asset for Agnico Eagle with a current mine life of 10 years (until 2032). Consisting of underground and open-pit mining, the Melidine mine has over 4,025,00 oz in gold reserves across seven gold deposits. Six of the gold reserves are in the mine plan are carried out through 12 open pits and two underground mining operations.

For over 30 years, Agnico Eagle has been operating in the Canadian Arctic, with commercial production commencing in 2019. They have implemented measures to reduce emission to air, water and land whilst minimising their footprint. With on-site camp facilities available for all staff, Meliadine Mine can cater to almost 500 people whilst keeping environmentally sustainable. Due to their remote location, all materials need to be delivered by plane or boat.

Saline water treatment for Meliadine Mine

Aginco Eagle commissioned Minetek to assist with site water balance control and management of excess brine generated by the reverse osmosis plant. Their new underground mine required volume reduction to support development for site water balance control. In addition to their requirement of managing excess brine water with limitations around brine storage. The Meliadine mine site is one of a handful of mine sites across the globe only accessible by air which poses complex logistics and high costs to dispose of this water via traditional methods.

Water management solution

To meet the water management requirements of Agnico Eagle’s Meliadine Mine, Minetek supplied 5x 400/200 evaporators for brine water evaporation and water balance control. The evaporators are in place to treat excess brine generated through reverse osmosis, assisting with volume reduction for water balance control.

Minetek’s wastewater evaporators can vaporise water ranging from pH 2.2 to pH 12 including brine or caustic water. Our units can evaporate up to 50% of spray as pure water vapour, returning the remaining volume of droplets to the feed pond. This system can process 2000 GPM (450m3/hour), with the system air freighted to the site to meet urgent delivery requirements. Our evaporators are estimated to remove 500 m3 per day per unit when operated for 24 hours with ideal wind and relative humidity.

Client: Agnico Eagle

Site: Meliadine Mine

Location: Nunavut, Canada

PROBLEM

- The new underground mine requires volume reduction for site water balance control at Meliadine Mine

- Issues with managing excess brine generated by the RO plant.

IMPACT

- Limited storage space for brine storage on the Meliadine Mine site

- High cost & complex logistics to dispose of brine using traditional methods

SOLUTION

- Minetek supplied 5 x 400/200 stainless steel mechanical evaporators for brine water evaporation and water balance control.

- 2000 GPM (450m3/hour) system

- Air freighted to Meliadine mine site located in Nunavut, Canada in order to meet urgent delivery requirements.

Interested in learning more about our water management projects or noise reduction case studies? Discover how you can reduce risks and costs associated with managing wastewater by leaving your details below.