Tritton Copper Mine is located near the town of Nyngan and Cobar in central New South Wales. The combined ore production from both the Tritton Mine and the Murrawombie Mine based at the same site is 1.8 million tonnes per annum. Tritton Mine has been in operation since late 2002 and is currently one of the largest underground mines in Australia. The mine produces copper concentrate, which is transported to smelters in Asia for further processing. Utilising a number of modern mining techniques and equipment, including longwall mining and computerised control systems.

Tritton mine ventilation requirements

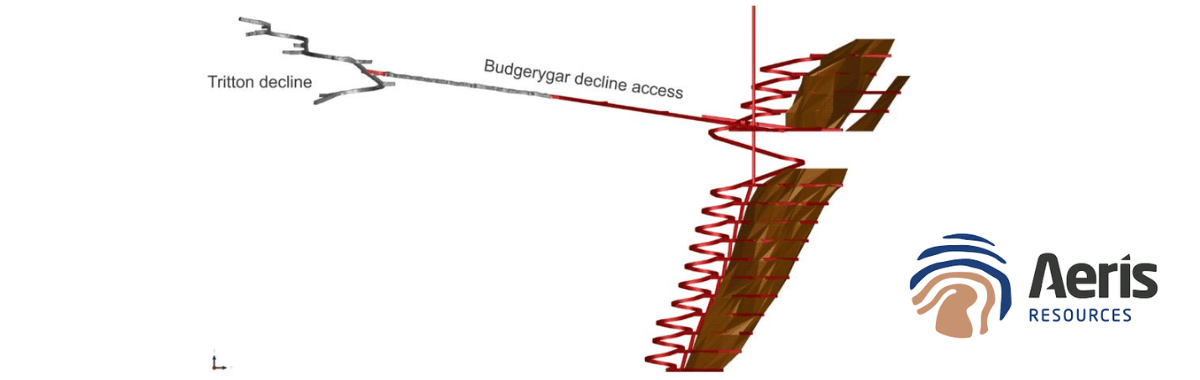

Aeris Resources has continued drilling extensions to the deposit at a depth of up to 1,500 meters. This extension required a ventilation solution for the development of the decline. The decline length and fresh air raise scheduling posed a unique challenge for Aeris Resources which owns Tritton copper mines. Standard fans would not meet the requirements needed at this depth, due to high pressure and drive size limitations.

Minetek has been able to support Tritton Mine by providing a unique patented ventilation solution using only a single fan and delivered within a tight time frame. This allowed operations to meet and exceed development targets, minimize shutdowns and reduce operational and energy costs. Tritton Mine has since been able to increase production by 30% since installing Minetek’s 375kW auxiliary High Output (H.O) Axial Fan with integrated Performance-on-Demand (P.O.D) system, Soft Starter, Programmable Logic Controller (PLC) and programming. Minetek’s innovative ventilation solution has not only helped Tritton Mine to improve their operations but has also set a new standard for underground mines around the world.

Ventilation challenges and considerations

Tritton Mine’s challenging conditions meant there were several essential requirements to meet when choosing their ventilation solution. According to Dan Stevens, Tritton Mine Superintendent “we wanted a single fan installation that could deliver 50 – 60 m3 per second, to support a bogger and truck behind the 1000 meter development mark”.

The solution needed to meet the required duty points in both air flow and pressure. The overall size and number of fans required also had to be considered, as a larger fan would include higher initial operational and economic costs while installing many fans would interrupt operations and include multiple shutdowns.

Additional features were paramount to the Tritton Mine team. Variable power, pressure and performance that could be controlled from the surface of the mine, and integration into the existing software system were all elements considered in the decision-making process.

Tritton Mine had initial concerns that a single Minetek fan would not be able to meet their requirements, as larger or multiple fans would traditionally be used for projects of this length and depth. Minetek provided technical data that guaranteed the solution would be able to meet Tritton Mine’s needs.

Tritton copper mine ventilation solution

The Tritton Copper Mine site needed the solution engineered and installed urgently. Minetek were agile and worked closely with Tritton copper mine while adapting to last-minute specification changes and delivering on time. They made the decision to do the job once and do the job right, that and the compact design of the fan were the main reason they chose Minetek.

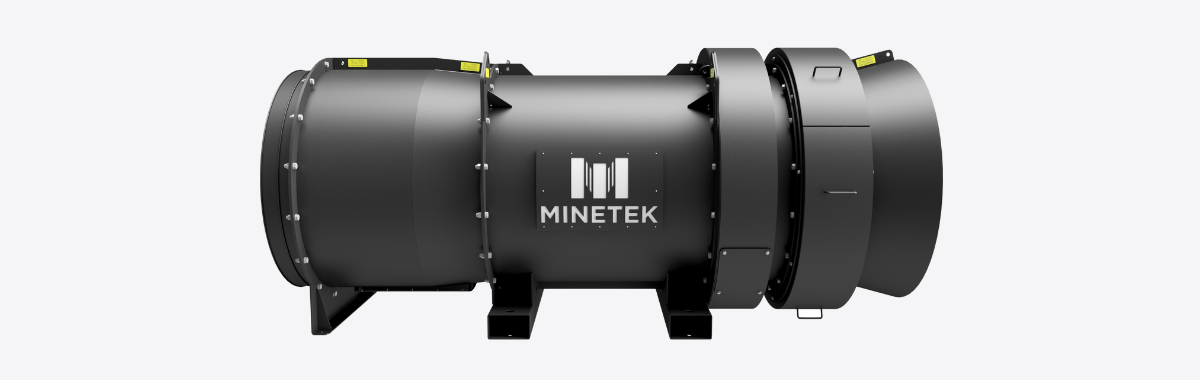

The solution negated the need for larger or multiple fans that would complicate installation and need maintenance shutdowns throughout the development. The standard 1400mm diameter size of Minetek’s fan allowed for a single installation.

Minetek’s fan is inherently quiet compared to traditional and this minimizes the overall length from 7m to 4m. The shorter size improved installation as it is safer to lift, and economic to install, with no need to excavate extra for head height.

Minetek continued supporting Tritton Mine with best practices for installation which helped to expedite the project. It was also important that the programming could bridge the existing systems on-site. Minetek developed a tailor-made solution to assist with the integration

High Output Axial Fan

After conducting research and analysis of the site, Minetek provided one 375kW auxiliary High Output (H.O) Axial Fan with an integrated Performance-on-Demand (P.O.D) system, Soft Starter, Programmable Logic Controller (PLC) and programming.

The High Output Axial fan is designed with the mining industry in mind, and the steel-fabricated impeller allows for operation at pressures previously thought impossible for an axial fan. This style of fan has been designed to withstand extreme amounts of dust and will have a prolonged life in even the harshest conditions.

Minetek’s P.O.D patented system allowed Tritton Mine to have performance, power and pressure on demand. The ability to adapt the fan to match the exact activity underground, coupled with the quality of the fan were both vital components when choosing Minetek.

Overall, Minetek was able to reduce Tritton Mines ventilation power consumption by 55%. This figure is based on 24 hours of operation, 365 days of the year, in comparison to 2 x twin 110kW fans. Our single fan install provides faster re-entry times, with single, low profile ducting, PLC screen surface control and reduced installed power.

Benefits include performance, power and pressure on demand with Minetek’s integrated POD system. With a power range from zero to full load, you can provide the correct amount of air, at the right time. Saving you in power costs by reducing consumption, with no VSD required for control, you have both automated or manual configurations available.

Interested in learning more about our fan capabilities? Please leave your details below and we will send you more information.