MINETEK PROJECTS

our latest case studies & downloads

See how we’ve kept mines on the move worldwide. Our ventilation, sound attenuation and water evaporation solutions have saved companies millions of dollars through minimal downtime, increased production and by meeting regulatory requirements.

Our capabilities feature

Primary booster fan

Engineered to safely increase Minetek’s underground ventilation has many benefits over standard solutions. Reduce power consumption costs by up to 56% with Minetek’s ventilation technology. The flexible airflow using the Performance On Demand (POD) system can ramp up or down, accommodating changes in activity throughout the life of the mine.

Latest downloads:

project case studies.

Located in Western Australia, Thunderbox mine is a mesothermal lode gold deposit. Minetek were commissioned to develop temporary Primary Booster Fans for Northern Star Resource’s Thunderbox mine.

Tags: Western Australia, Underground ventilation, gold mine, HO series 375kW fan, turn-key project.

Minetek were commissioned to manufacture a turn-key sound attenuation solution for the Caterpillar 775G dump truck. The goal of this project was to reduce the machine’s operating noise down to the strict mine noise level, without compromising its operating capacity or adding excess weight to the machine.

Tags: Caterpillar 775G, sound attenuation, turn-key package, noise reduction.

Viper Mine’s tailings storage facility is at capacity reaching the end of its useful life after 39 years, and Knight Hawk Coal commissioned Minetek to assist with the dewatering and reclamation of this storage facility.

Tags: Illinois, United States, 200/100 Water Evaporator, coal mine, tailings storage facility.

Newcrest Mining Limited’s Cadia mine site is one of Australia’s largest gold mines. Cadia approached Minetek to provide a fan suitable for extracting dust caused from the dumping and crushing process underground.

Tags: New South Wales Australia, Gold Mine, Copper Mine, Surface ventilation, Underground Ventilation, 90kw High Output Axial fan.

Minetek were commissioned to design and manufacture a turn-key sound attenuation solution for the Caterpillar 793D dump truck. This project aimed to reduce machine operating noise down to the site noise level without compromising machine integrity,

airflow, maintenance and access ability.

Tags: Caterpillar 793D, sound attenuation, turn-key package, noise reduction.

Minetek’s Coal-Fired Power Station client, located in Montana, United States, was dealing with significant volumes of brine wastewater and approached Minetek for an efficient and cost-effective solution.

Tags: Montana, United States, coal-fired power station, 400/200 Water Evaporator, continental climate.

The Agnew Gold Mine experienced challenges with its existing primary ventilation circuit. Minetek was commissioned to develop a Primary Booster Fan solution. This solution was an Australian first for a fan of this combined size and technology.

Tags: Western Australia, primary booster ventilation, performance on demand, 1100kW.

The Caterpillar 789C Dump Truck is engineered for performance, designed for comfort, and built to last. Developed specifically for high-production mining and hauling applications, the 789C keeps material moving at high volumes at a lower cost per ton.

Tags: Caterpillar 789C, sound attenuation, turn-key package, noise reduction.

Las Lagunas mine is situated 100km northwest of the Dominican Republic

capital of Santo Domingo in the Caribbean. This gold and silver mine is currently operated by Panterra Gold, previously known as EnviroGold. The Las Lagunas Gold Tailings is a retreatment project which involves

reprocessing previously unrecovered gold and silver refractory tailings.

Tags: Dominican Republic, gold tailings retreatment, water management, water evaporation.

Exploration is ongoing at Granny Smith Mine which drove the need for a greater Life of Mine (LOM) than originally anticipated. Granny Smith Mine was in need of a ventilation upgrade that offered the variability of airflow and power needed today, but also at LOM. The site also demands a heavy-duty ventilation system able to withstand the highly saline air conditions experienced.

Tags: Western Australia, primary booster ventilation, performance on demand, 1100kW.

The importance of effective noise management for the mining industry cannot be overstated. Noise control has grown in intensity as pressure to meet environmental regulations increases and government bodies like the Environment Protection Authority (EPA) continue to enforce strict requirements and penalties.

Tags: strategies for noise control, sound attenuation, noise reduction.

Chapada Mine needed to mitigate the risk of water impacting on their production and as such the site urgently required a water management solution that could deliver both dewatering for their central pit and effluent management for their Tailings Storage Facility (TSF). The need was a

direct result of Goiás’ tropical climate and subsequent high rainfall totaling on average 1500mm (59.1 inches) annually.

Tags: Brazil, water management, water evaporation, tropical climate.

29Metals commissioned Minetek for a solution to achieve their immediate short-term ventilation needs, that could grow with the mine’s longer-term objectives.

Strict project targets around infrastructure and power constraints were a challenge but Minetek was able to deliver a turn-key solution that provided operational savings.

Tags: Western Australia, Primary Booster Fans, performance on demand, underground ventilation.

The Liebherr R9800 is one of the largest OEM mining excavators in the world. At 800 tonnes it is designed for large-capacity mining operations and can work on almost any surface. Developed as the optimal loading tool for large-scale mining operations, the R9800 is able to achieve even the most challenging of targets. Powered by two V16 cylinders, each with a displacement of 537 cubic metres, the Liebherr R9800 can move up to 240,000 cubic metres of dirt and rock per day.

Tags: Liebherr R9800, mining excavator, sound attenuation, noise reduction, turn-key solution.

Agnico Eagle urgently required a water management solution that could support the site’s water balance control as well as manage the excess brine generated by Meliadine’s Reverse Osmosis (RO) plant, all whilst working with the site’s limited storage space for brine.

Meliadine Mine’s challenges were also intensified by the site’s limited accessibility. The mine site is only accessible by air, resulting in additional logistical challenges as well as high costs for traditional water and brine disposal methods.

Tags: Meliadine mine, water management, water evaporation.

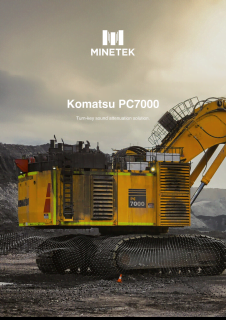

Reducing the machine noise emitted by Komatsu’s PC7000 can assist with increased operating hours, resource recovery, carbon emissions and stakeholder satisfaction.

Minetek was commissioned to design and manufacture Australia’s first turn-key sound attenuation solution for the Komatsu PC7000 mining excavator. This solution was specific to the NSW Hunter Valley mining region with strict noise limitations of 116dBA to adhere to.

Tags: Komatsu PC7000, sound attenuation, noise reduction, turn-key solution, mining excavator.