Noise control is often one of the less significant considerations when planning and implementing mining developments. While environmental regulations need to be met, noise does not pose an immediate risk to the life of miners or the community at large.

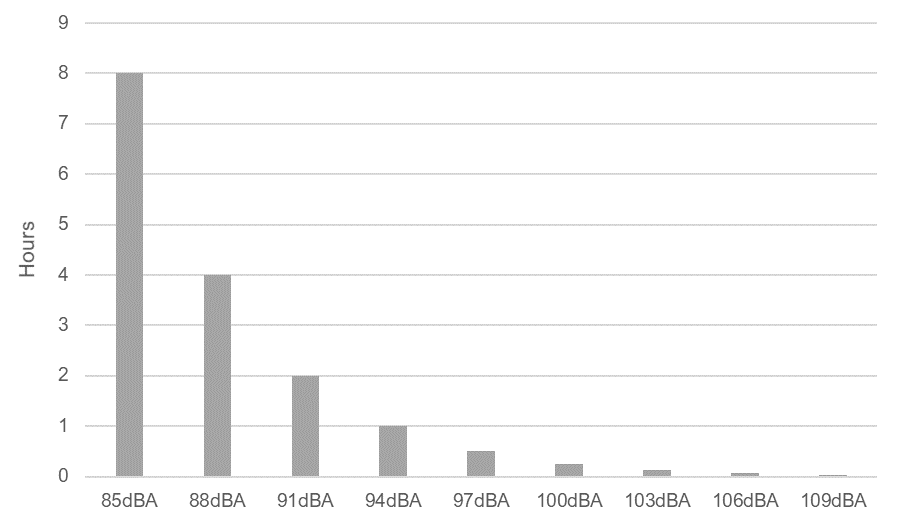

Mine sites often choose to reactively control noise pollution only once an incident has occurred, as either a breach of regulation or pressure from the local community emerge. However, noise is a generic hazard common to the entire industry and all mining operations. One in four mineworkers has hearing issues, with four out of five miners having a hearing impairment by the time they reach their mid-60s. Industrial Deafness compensation claims can be costly to the industry. Hearing loss, compensation payments, and public awareness are all on the rise.

Proactive sound attenuation is the best noise control solution, helping to mitigate issues and reap the immediate rewards of strategic noise dampening without economic loss of downtime or fines. Minetek can help sites assess all elements of sound suppression and embed sound as a key consideration in all safety and environmental initiatives.

What are the options for noise control?

There are three main types of engineering noise control in industrial workplaces. Each of these methods comes with factors that need to be addressed. These are:

- Employer control

- Contrôler le bruit à la source

- Contrôle de la propagation du bruit

1. Employer Noise Control

This is achieved by workers wearing hearing protection.

Considerations

Employer PPE is the easiest sound control method but should be seen as an additional supplement on top of proper noise control. Hearing protection relies on individual workers to fit and wear protection and does not control site noise or vibrations that may cause environmental or community breaches.

2. Controlling Noise at the Source

This is achieved by the substitution of processes, work methods, materials, or equipment. Specification of quieter machines or minimising the number of machines running at a given time.

Maintaining equipment or well-designed machines with sound in mind can also mitigate noise. The reduction of mechanical shock between parts, friction or vibration can reduce the sound.

Considerations

While controlling noise at the source is a reasonable method for sound control, not all options are realistic. Running fewer machines or limiting production to certain times can seriously impede the site’s ROI, as seen at New Acland in NSW.

Additionally, choosing to change work methods, processes or equipment can be both timely, and costly, and often come with additional safety assessments and red tape.

Substituting machinery or machinery parts to reduce noise is the best option to control noise at the source. There are several complexities that need to be considered when doing this, and many offerings on the market, such as fan substitution, sacrifice machine performance, power and longevity in the name of noise suppression.

Minetek can assist in a full assessment of viable options to control noise at the source, that won’t reduce power, performance or profitability of the equipment or site.

3. Controlling Noise Propagation

This is achieved by blocking the sound waves from travelling, either using barriers, enclosures, reactive or dissipative mufflers, reverberation control or active noise control.

Considerations

Controlling noise propagation is another feasible option if performed correctly. Sound suppression idlers, engine attenuation, and acoustic engine enclosures are all options for great reduction however, just like controlling noise at the source, due care must be taken to not overheat, crowd, or block the engine. Many companies in the market fail to consider the longevity of equipment, choosing to sacrifice quality for immediate cost savings.

Incorrect or low-quality sound suppression can severely hamper a machine’s performance and life span. Replacing burnt-out mine equipment will ultimately wind up being far more costly than investing in a correct sound attenuation solution.

There’s also an environmental element to consider here as well. Maintaining mechanical and combustion efficiency will prevent equipment from chewing through petrol and driving down air quality on site.

Environmental and community awareness is increasing scrutiny of industry noise. Sound attenuation is not only important for employer safety, but poor noise control can raise expenditures due to machine replacement, fines, compensation payouts and strict limitations to production schedules.

We offer onsite sound assessing, consultation, custom engineering, installation, servicing, and guaranteed results. Make Minetek part of your sound attenuation strategy and set your site up for success.