What is sound attenuation?

Sound attenuation is a sound reduction by absorption. The energy from sound is transferred into heat (energy). In sound attenuation, the medium used for noise control will get warm. The material used to absorb the sound as well as the angle the sound hits the material both play an important role in the effectiveness of this technique.

What is sound dampening?

Sound dampening obstructs the sound by reflecting the waves away from the area. Walls, doors, and windows are examples of this, as they prevent sound waves from travelling through, often instead bouncing them back in another direction. The thickness of the material and how dense it is will play a role in its effectiveness as well.

So, to recap: sound attenuation absorbs the sound while sound dampening reflects it. Both are effective noise control strategies that can be used depending on the situation.

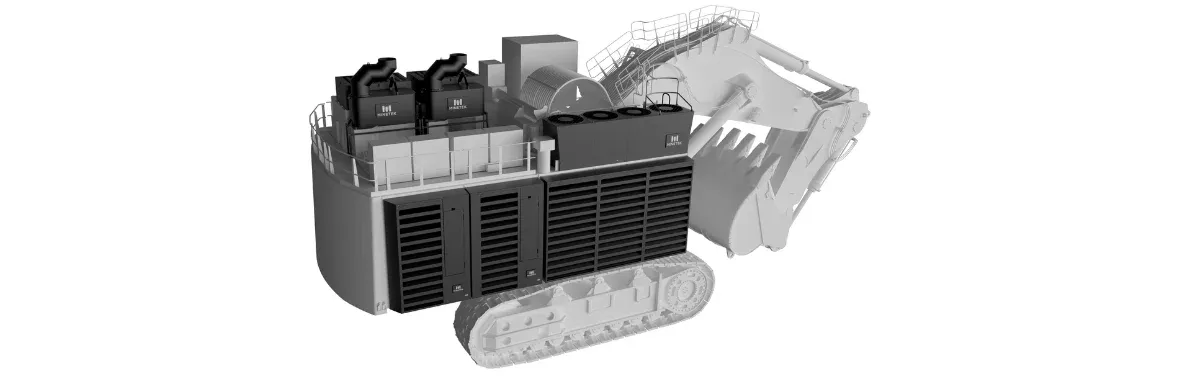

Minetek machine attenuation packages

At Minetek we produce the world’s quietest mining equipment. With over 1,500+ mining machines attenuated, our experienced team will travel to your site for certification and installation of your sound attenuation package.

The scope of any Minetek sound solution is to develop flexible solutions which not only permit noise to be attenuated in mining machinery but also be innovative in design in order to reduce the weight of any added component without compromising on machine integrity and without compromising airflow, maintenance and operating ability.

Minetek understand the negatives experiences with incorrect airflow design can cause the following

-

- Decreased performance and overheating

-

- Excess vibration can result in excessive noise

-

- Equipment failure

We understand the common causes of deficient performance of a fan/system

-

- Improper inlet or outlet conditions

-

- Non-uniform inlet or outlet flow

-

- System effect

-

- Detrimental effect on fan performance due to airflow disturbances in close proximity to the fan – either upstream or downstream

Minetek understand the issues associated with the cost of downtime

-

- We ensure that each sound attenuation kit is designed with ease of maintenance in mind, ensuring that maintenance and service points are easily accessible.

Regulatory noise testing

Minetek provides a complete range of noise testing options for each mining client it deals with. We work closely with our clients to develop practical mitigation solutions that are workable for the mining company and they can demonstrate that they meet regulatory and community expectations. All types of noise testing including compliance testing as per the ISO 6393/6395 Standard, sound intensity testing, mobile fleet screening and operator noise exposure.

Refurbishment and replacement components

Minetek provide total refurbishment or replacement of sound packages and exhaust componentry. Components such as acoustic media, exhaust systems, engine bays and bonnets of mining machinery can be replaced or refurbished to reduce noise levels. Minetek stocks many replacement radiator attenuators, exhaust packages and media kits in our warehouses located in both Sydney and Perth, Australia.