Metals and minerals power our world, from the cement beneath our feet to the steel in our homes and the screens we use daily. Mining makes this possible, but underground operations face serious risks: cave-ins, explosions, and extreme temperatures. Adequate underground mining ventilation is the cornerstone of safety, ensuring clean air and stable conditions for miners. Minetek’s advanced ventilation solutions drive compliance and performance, safeguarding lives and operations.

The role of underground ventilation

Underground mining ventilation ensures a safe, controlled environment by delivering sufficient airflow to dilute and remove hazardous contaminants like dust, diesel fumes, and toxic gases. Minetek’s advanced ventilation systems, tailored to the scale of any operation, prioritize miner safety and compliance with stringent government and OSHA regulations.

Poor air quality poses serious risks, including pneumoconiosis, a lung disease caused by prolonged exposure to respirable dust, which can lead to disability or premature death. Confined spaces and vehicle emissions further degrade air quality, while gas build-up, like methane, risks explosions without proper monitoring and ventilation. Minetek’s Performance On Demand (POD) system dynamically adjusts airflow to mitigate these hazards, ensuring safe contaminant levels.

Ventilation also regulates extreme temperatures, from freezing cold to dehydrating heat, protecting miners, machinery, and mine structures from damage or collapse. A well-designed ventilation plan, powered by Minetek’s POD maps hazards and optimizes airflow, driving safety, efficiency, and regulatory compliance across underground operations

Primary fan ventilation

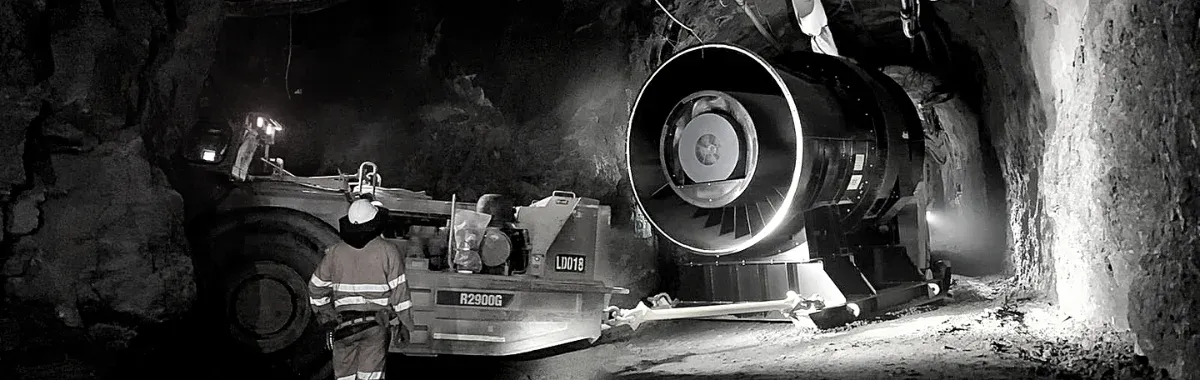

Primary ventilation is the backbone of mine safety, channeling fresh air through large surface fans to dilute dust, gases, and heat across underground circuits. Minetek’s primary ventilation fans stand out with power-efficient designs, robust construction, and adaptable airflow, ensuring compliance with governing body regulations like the US Federal Mine Safety and Health Act. Unlike conventional systems, Minetek guarantees a measurable return on investment (ROI) by optimizing energy use and enhancing system longevity, making it the preferred choice for large-scale mining operations.

Secondary fan ventilation

Secondary ventilation targets specific underground zones, circulating air in dead-end headings and service areas where primary airflow is limited. Minetek’s High Output (HO) Axial Fans and Raptor Fan Series, available in impulse-bladed and vane axial models, are 40% shorter, 10% lighter, and over twice as powerful as comparable traditional fans. Their compact design and low-profile ducting reduce the need for multiple fans, cutting power consumption. With PLC surface controls and the ability to surge past critical duty points to clear gases quickly, Minetek’s secondary fans enable faster re-entry and superior performance for long duct runs.

Underground ventilation requirements for compliance

The site’s mine manager is responsible for ensuring that a plan of the mine’s ventilation system is kept at the mine. This helps to communicate the direction, course, and volume of air currents and the position of all air doors, stoppings, fans, regulators, and ventilating devices in the mine. Managers must understand the impact the following factors have in determining the effectiveness of the ventilation planning process:

- Underground mine plan and schedule

- Mine design and method

- Airflow modelling

- Development of ventilation plans and schedules

- Diesel equipment

- Naturally occurring and man-made contaminants

The mine manager must also ensure that the following ventilation requirements are met.

- The air supply for any ventilating equipment used underground is obtained from the purest source available.

- The recirculation of air within any secondary ventilation circuit is maintained at the minimum level that is practicable.

- Where practicable, contaminated return air from any secondary ventilation circuit is exhausted directly to the primary return air exhaust system.

Underground fans are controlled by an approved system that will ensure the mechanical integrity of the fan and its associated ducting. All mine workings, plants, and equipment located within any ventilation circuit are certified as explosion-proof. All air doors are constructed and installed in accordance with the requirements specified in the door schedule.

Implementing effective ventilation plans

Translating regulatory requirements into actionable ventilation plans demands precision and adaptability. Minetek’s advanced systems, powered by the Performance On Demand (POD) and Mine Air Control (MAC) technologies, streamline this process by providing real-time airflow adjustments and centralized surface controls. These solutions enable managers to monitor and respond to changing conditions, such as gas build-up or equipment demands, ensuring continuous compliance with safety standards. By reducing energy consumption and minimizing maintenance downtime, Minetek’s ventilation systems not only meet regulatory mandates but also enhance productivity, delivering a measurable return on investment for mining operations worldwide.

The critical role of underground ventilation in mining

Robust underground ventilation is non-negotiable for miner health, equipment reliability, and structural integrity. It mitigates risks like pneumoconiosis, methane explosions, and temperature extremes that threaten lives and operations. Minetek’s comprehensive range of primary, secondary, booster, and crusher ventilation fans addresses these challenges with compact, durable, and energy-efficient designs. Backed by the POD and MAC systems, Minetek ensures regulatory compliance, reduces energy costs, and delivers a strong ROI, redefining safety and performance in underground mining. Contact Minetek today to explore tailored ventilation solutions for your operation.