Imagine a mining industry where profitability and sustainability aren’t in conflict. Where every operation moves forward with precision, efficiency, and a lighter environmental footprint, facilitating mining decarbonisation. This isn’t a vision for tomorrow, it’s what Minetek is delivering today. As the world accelerates toward net zero, the mining sector faces increasing pressure to reduce carbon emissions without compromising productivity.

Minetek, a global leader in innovative mining solutions, steps in with bold, deliberate strategies that reduce emissions, optimise operations, and align with both regulatory expectations and industry demands. From energy-efficient ventilation systems to sustainable water management technologies, we’re transforming how mines operate, proving that emissions reduction is not only possible but practical.

In this article, we explore how Minetek is helping mine managers, consultants, engineers, and project teams take decisive steps towards a more sustainable and resilient future.

Mining industry carbon emissions.

Mining is a critical pillar of the global economy, supplying essential minerals for infrastructure, electrification, and the production of clean energy. Historically powered by diesel machinery, coal-fired plants, and energy-intensive underground systems, mining’s carbon footprint runs deep. Scope 1 and 2 emissions dominate, with Scope 3 (supply chain and downstream) further compounding challenges.

The 2015 Paris Agreement was a wake-up call, pushing industries to align with a 1.5°C pathway. By 2023, mining giants like Rio Tinto and BHP committed to net-zero targets by 2050, backed by mounting investor and regulatory pressure. The International Council on Mining and Metals (ICMM) pledged all 650+ of its sites to mining decarbonisation. Alongside these shifts, emerging technologies and operational innovations are driving real change. Minetek, with over 40 years of engineering excellence, is at the forefront, offering integrated solutions that balance sustainability and performance.

Pathways to mining decarbonisation

-

Tackling energy-intensive mining operations

Mining’s energy demands are high, but targeted innovation is making an impact. Ventilation alone can account for up to 49% of a mine’s energy consumption. Minetek’s high-output axial fans offer precision airflow and drastically reduce Scope 1 and 2 emissions. With global frameworks like the EU’s Carbon Border Adjustment Mechanism (CBAM) pressuring companies to act, forward-thinking miners are investing in long-term solutions, not quick fixes.

-

Balancing output with carbon emission reduction

Sustainability is no longer optional, it’s a strategic necessity. As highlighted by White & Case, the industry must navigate rising demand for critical minerals alongside strict mining decarbonisation targets. Minetek’s integrated air, water, and power systems help mines meet both needs. Real-time adaptive ventilation and advanced evaporation systems are enabling operations to meet production targets while maintaining compliance and minimising impact.

-

Advancing net-zero through renewables

Net-zero ambitions require radical transformation. The IFC’s Net Zero Roadmap (2023) stresses the role of renewables and electrification. Backed by initiatives like the U.S. Department of Energy’s $475 million investment in mine-site clean energy (2024), mines are accelerating the shift. From solar-powered infrastructure to systems like Minetek’s ventilation and water solutions that minimise fossil fuel use, the pathway to electrification is being paved, one solution at a time.

-

Meeting regulations with smarter air systems

Tighter regulations demand more from mining operations. Air management, often responsible for 40% of a site’s energy use, is a clear target. Minetek’s high-performance fans offer immediate results, —reducing emissions, enhancing safety, and ensuring compliance. With global policies like CBAM and national net-zero pledges gaining momentum, miners need solutions that meet standards without sacrificing efficiency. Minetek delivers both.

-

Building resilience with better water management

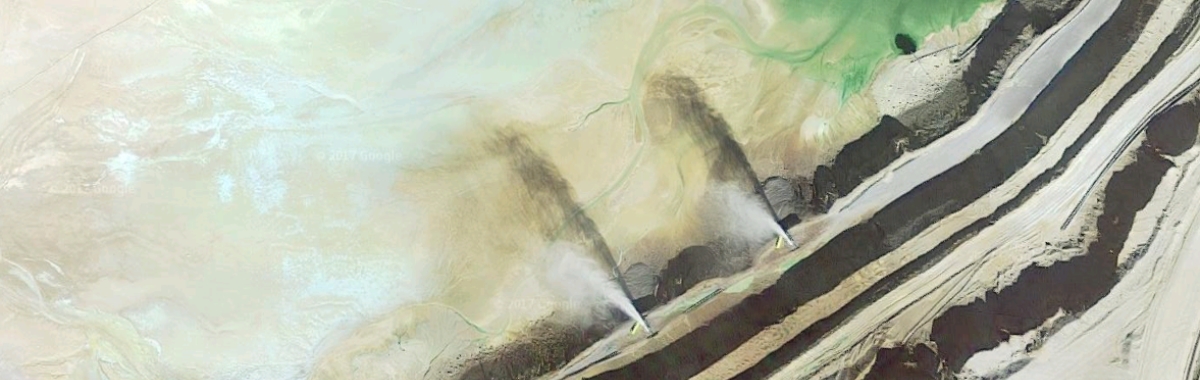

Resilient operations require sustainable water practices. Minetek’s mechanical evaporation systems are engineered to reduce risk and meet strict environmental requirements like those outlined by the GISTM. With water scarcity threatening 30–50% of global copper and gold production (McKinsey, 2020), our solutions help mines manage water responsibly, safeguard compliance, and ensure long-term viability.

-

Decarbonising while scaling operations

As demand for transition metals surge, miners face a dual challenge: scale up while also cutting carbon emissions. Minetek’s ventilation and evaporation systems reduce Scope 1 and 2 emissions, supporting ambitious goals like China’s 2060 neutrality goals. With proven performance across 2,800+ projects in 60 countries, our solutions are already helping operations grow sustainably.

How does mining increase carbon emissions?

Mining operations significantly contribute to carbon emissions through energy-intensive processes. These involve operational activities from drilling to blasting and ore processing, which rely heavily on fossil fuel-powered machinery. Heavy mining equipment, such as haul trucks and excavators, emits substantial CO2, while ventilation systems in underground mines consume vast amounts of electricity, often sourced from coal or gas. Additionally, land clearing for mining sites releases stored carbon from soil and vegetation, exacerbating emissions.

Minetek’s innovative ventilation, noise reduction, and water evaporation solutions empower mining companies to cut not just coal mining carbon emissions but also open-cut and underground mining emissions, achieve regulatory compliance, and drive sustainable operations without compromising productivity.

Underground ventilation

Ventilation is one of the most energy-intensive systems on site, and we’re redefining the standard. Our High Output Axial Fans and Modular Air Control (MAC) systems deliver unmatched efficiency and control. By optimising airflow underground, these solutions cut Scope 1 and 2 emissions, reduce costs, and enhance safety. We’re proving daily that high performance and sustainability are not mutually exclusive.

Sound attenuation solutions engineered for compliance

Reducing environmental impact in mining takes more than mufflers, it demands engineered, site-wide solutions. Minetek Sound delivers proven noise reduction systems that integrate seamlessly with mining operations. Our solutions are designed to reduce sound emissions at the source, improve operational performance, and ensure compliance with tightening noise regulations, without compromising productivity.

Water management

Water is a finite resource and increasingly under pressure. Our world-leading mechanical evaporation systems handle a wide range of water qualities with unmatched efficiency. Whether you’re mitigating discharge risks or meeting strict regulatory standards, Minetek helps you conserve resources and enhance your ESG performance.

A cleaner mining future with Minetek

Minetek isn’t just a supplier, we’re your partner in mining decarbonisation. With solutions that actively reduce emissions across air, water, and energy systems, we help mining operations meet their sustainability goals without sacrificing performance or profitability.

As global leaders set the agenda for a low-carbon future, Minetek is enabling the mining sector to rise to the challenge. Ready to transform your site? Contact Minetek to learn more.