Metals and minerals are essential to our everyday lives. No matter the product – from the cement we talk on, to the computer screen we work on, all items depend on mining production today for our society function as we know it.

Mining has been an integral part of human history since ancient times when people first began exploring below ground level looking at what they could find down there. Cave-ins, explosions, and extreme temperatures are some of the most perilous hazards observed in underground mining. Underground mining ventilation, however, is the most critical safety aspect in the operation of an underground mine.

The aim of underground ventilation

地下 mining ventilation aims to control the environment by providing enough air to dilute and remove contaminants such as dust, diesel fumes, heat, and bad air. There are many types of ventilation fans used in mining depending on the size and scale of the operation, but all fans work to do the same thing – keep miners safe while they’re working.

Air pollution remains a prevalent issue for miners, with many at risk of developing a lung disease called pneumoconiosis. This can occur when miners are exposed to airborne respirable dust for long periods of time, leading to potential impairment, disability, and in extreme cases premature death.

Confined spaces, minimal ventilation and underground vehicle emissions can all compromise air quality underground. The main objective of an underground ventilation system is clear: provide air flows in sufficient quantity and quality to dilute contaminants to a safe amount.

Ventilation requirements are governed by government regulations in many countries. In QLD Australia, the Coal Mining Safety and Health Regulation 2017 sets out the requirement for a ventilation plan while also giving guidance on how to achieve an effective ventilation system.

The key to an effective underground mining ventilation system is good planning and design. By understanding all the potential hazards and mapping out a ventilation plan that takes these into account, miners can be sure they are safe while they work.

Underground mining poses hazards, including the build-up of methane and other gases along with limited oxygen. Without proper ventilation, this could result in explosions and multiple fatalities. Gas build-up must be monitored closely with evacuation and shut down procedures in place until the levels subside.

Air ventilation can dilute and remove toxic and potentially explosive gases. It is also necessary for regulating the temperature inside the mine. Temperature levels in underground mines range from extremity-numbing cold to such heat that can cause dehydration in a matter of minutes by profusely sweating.

It’s not just humans that are negatively affected by becoming sluggish in extreme heat or cold. Machines can overheat, freeze, or stop working in harsh environments. Even the support structure of the mine can become compromised in these conditions, leading to warping and collapse.

Primary & secondary underground ventilation fans

There are two main types of ventilation used in underground mines: primary and secondary. Typically primary fans are typically located at the surface while secondary fans are located underground. The main difference between primary and secondary ventilation is the size of the fan and the amount of air that is being moved. Primary ventilation is typically used to move a large volume of fresh air into the mine while secondary ventilation is used to help circulate the air that is already underground.

Efficient ventilation is critical for production and energy efficiency, with ventilation alone contributing between 42% and 49% of a typical mine’s energy cost. Minetek’s innovative engineering has resulted in groundbreaking features that can deliver economic savings, durability and flexibility simply not possible with traditional fans.

The flexible airflow using the Performance On Demand (POD) system can ramp up or down, accommodating changes in activity throughout the life of the mine. Coupled with the Mine Air Control (MAC) system, Minetek’s fans automatically track vehicles moving into the heading and adjust the airflow accordingly. The system is controllable from the surface above and allows synchronisation of the entire ventilation system.

Primary fan ventilation

Primary ventilation is the main airflow that is used to dilute contaminants. It is typically delivered through large, powerful fans that are located at the surface and blow fresh air into the mine. The basis of any adequate underground ventilation is the adequacy of the primary ventilation system. This is the total mine air volume flow through the significant underground workings, typically splitting into parallel circuits. Unlike conventional fans or competitors, Minetek’s primary ventilation ensures power saving, durability, and flexibility while guaranteeing a Return on Investment (ROI).

Secondary fan ventilation

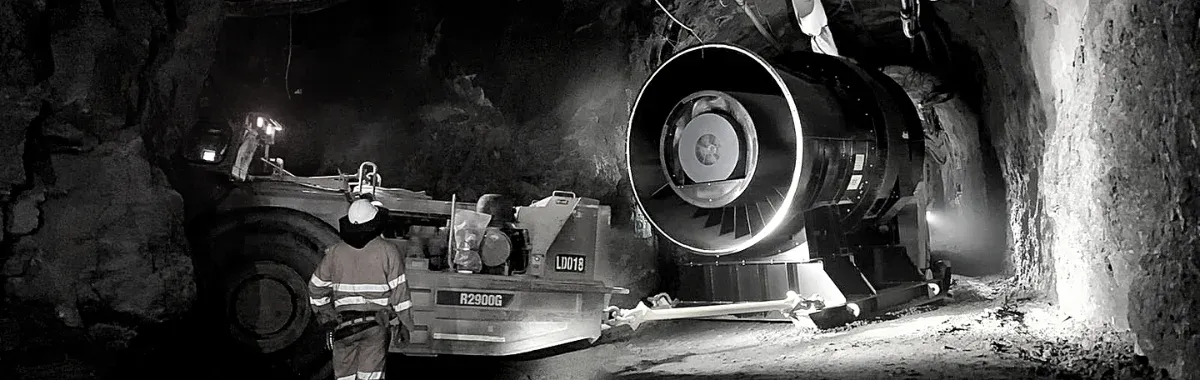

Secondary ventilation is used to help circulate air that is already underground, supplementing the primary airflow. It typically does not move as much air as primary ventilation and is delivered through smaller fans that are located underground. Secondary fans ventilate the development ends, stopes and services facilities that constitute secondary circuits tapped off the primary circuit or main through the flow of air. These headings are typically ‘dead-end’ configurations and may have multiple parallel headings where airflow is unavailable.

Although secondary ventilation is not as critical as primary ventilation, it’s essential to manage airflow and temperature in specific areas of exploration. Minetek’s Secondary Axial fans are compact, 40% shorter, and 10% lighter than standard fans with low-profile ducting. The high-pressure capability of Minetek’s High Output (HO) axial fan is more than double of traditional fans of comparable size. This results in fewer fans needed overall, reducing overall ventilation power consumption.

Minetek’s Secondary Fans models cater to both impulse-bladed and vane axial versions. The concentrated power of Minetek’s High Output (HO) Axial Fans makes them the ideal solution for long duct runs. Complimented by the need for only a single duct run, PLC screen surface control and the bonus of being able to surge the fan past the critical duty point to clear gases and dust for fast re-entry make Minetek the ideal choice.

Underground ventilation requirements

It is the responsibility of the site’s mine manager to ensure that a plan of the ventilation system of the mind is kept at the mine. This helps to communicate the direction, course, and volume of air currents, as well as the position of all air doors, stoppings, fans, regulators, and ventilating devices, in the mine. Managers must understand the impact the following factors have in determining the effectiveness of the ventilation planning process:

-

- Underground mine plan and schedule

-

- Mine design and method

-

- Airflow modelling

-

- Development of ventilation plans and schedules

-

- Diesel equipment

-

- Naturally occurring and man-made contaminants

The manager of the mine must also ensure that the following ventilation requirements are met:

-

- The supply of air for any ventilating equipment used underground is obtained from the purest source available.

-

- The recirculation of air within any secondary ventilation circuit is maintained at the minimum level that is practicable.

-

- Where practicable, contaminated return air from any secondary ventilation circuit is exhausted directly to the primary return air exhaust system.

The use of underground fans is controlled by an approved system that will ensure the mechanical integrity of the fan and its associated ducting. All mine workings, plants, and equipment located within any ventilation circuit are Certified as explosion-proof. All air doors are constructed and installed in accordance with the requirements specified in the door schedule.

Importance of underground ventilation in mining

Maintaining good ventilation underground is critical to the health and safety of miners. It is also important for managing temperature and air quality. Minetek’s primary, secondary, booster, bulkhead, long duct and development ventilation fans are designed to meet the specific challenges of underground mining ventilation. Our underground mining ventilation solutions are compact, durable, and flexible while guaranteeing a return on investment.