Underground mining is essential for resource extraction, but it comes with unique challenges—air quality being one of the most critical. The confined nature of underground spaces, combined with restricted natural airflow, makes them prone to the buildup of toxic gases such as methane and carbon monoxide. Diesel exhaust from machinery only worsens these risks. Without effective ventilation, these hazards can accumulate quickly, transforming a mine into a dangerous, even life-threatening, environment.

The Hidden Dangers of Poor Air Quality

One of the most severe threats in underground mining is the accumulation of flammable gases like methane. At high concentrations, methane can ignite, causing catastrophic explosions. Equally hazardous is carbon monoxide—an invisible, odourless gas that silently endangers lives. Even small doses can hinder oxygen delivery in the bloodstream, leading to poisoning and potentially fatal consequences.

Inhalation of fine dust particles, particularly in coal mining, can also lead to pneumoconiosis (black lung disease), causing long-term respiratory damage and irreversible lung conditions. This underscores the critical need for advanced ventilation systems to protect workers’ health.

The Crucial Role of Ventilation in Temperature Control

Air quality management extends beyond gas and dust—it’s also about temperature regulation. Depending on a mine’s depth and location, underground conditions can swing from dangerously hot to freezing cold. In deep mines, geothermal heat can cause extreme temperatures, raising the risk of heat exhaustion or heatstroke. Conversely, in colder regions, poor ventilation can result in hypothermia. Effective ventilation systems help regulate temperatures, creating safer, more productive work environments.

Meeting Legal and Regulatory Standards

Proper ventilation isn’t just best practice—it’s a legal requirement in many mining jurisdictions. For example, regulations in Western Australia mandate detailed ventilation plans tailored to each mine’s unique conditions. These plans factor in mine depth, mineral type, and equipment used, all to disperse harmful gases, control temperatures, and maintain airflow that protects worker health and safety.

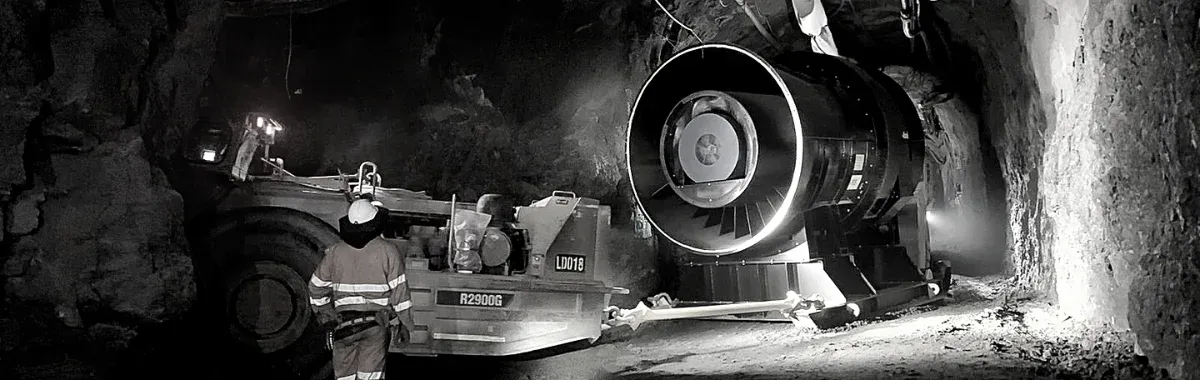

Minetek: Pioneering the Future of Mining Ventilation

For nearly four decades, Minetek has been a global leader in developing innovative, efficient, and cost-effective ventilation systems for underground mining. Our commitment to advancing technology and delivering customised solutions has helped mining companies worldwide optimise ventilation strategies, meet regulatory standards, and prioritise worker safety.

Revolutionising Airflow with Performance On Demand (POD) Technology

One of Minetek’s most revolutionary innovations is our Performance On Demand (POD) technology. Unlike traditional systems that rely on Variable Speed Drive (VSD) controls requiring constant monitoring and manual adjustments, our POD system uses single-speed fans that automatically regulate airflow based on real-time conditions. These intelligent fans adjust dynamically to provide the exact amount of air needed, enhancing safety through consistent circulation and effective dispersion of toxic gases and heat.

Maximising Energy Efficiency and Reducing Costs

Minetek’s ventilation solutions are designed with energy efficiency at their core. By eliminating the need for continuous high-speed fan operation, our systems can cut energy consumption by up to 50%. This not only reduces operational costs but also supports sustainability goals, delivering a strong return on investment while advancing environmental, social, and governance (ESG) objectives.

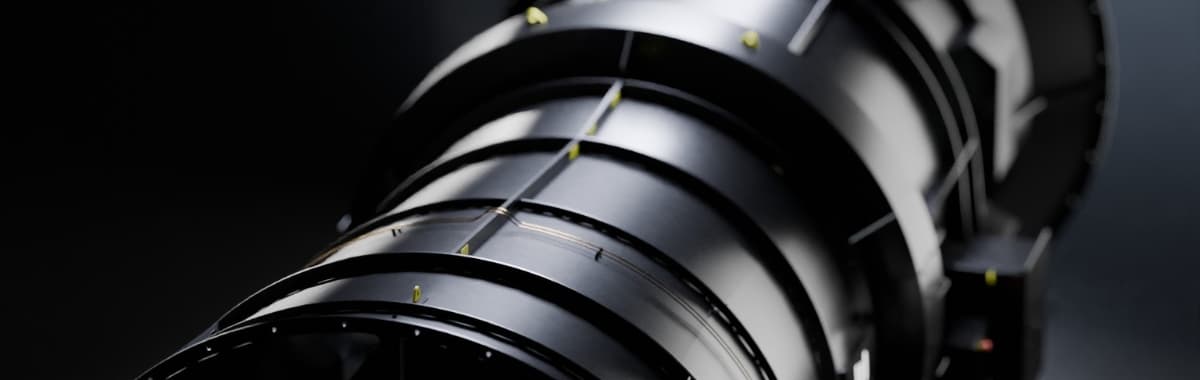

Engineered for the Toughest Conditions

Our ventilation fans are built to endure the harshest underground environments. With steel-fabricated impellers, they achieve pressure levels once thought impossible for underground operations. This rugged construction ensures exceptional durability, reduces maintenance needs, and minimises operational downtime—crucial for maintaining productivity in demanding mining conditions.

Minetek: Redefining Underground Ventilation Standards

At Minetek, we’re redefining what’s possible in underground ventilation. Our solutions not only enhance safety and regulatory compliance but also improve operational efficiency, allowing mining companies to boost productivity while reducing their environmental impact.

Whether it’s managing toxic gases, regulating temperatures, or improving energy efficiency, Minetek’s innovative approach ensures underground mining operations remain safe, sustainable, and profitable.