Mines can operate 24/7 if appropriate noise regulations are met. These are typically achieved through machine noise reduction strategies and sound attenuation. Open-cut mines are susceptible to increased noise levels due to the nature of their operations with heavy machinery often the primary source of increased noise on mine sites. Minetek Sound has developed sound attenuation solutions to ensure machinery is compliant with government regulators and set noise limits the mine must adhere to.

What are the implications of noise pollution on mine sites?

Mines are 24/7 operations, and anyone working or living near a mine site, without realising it can suffer from hearing and/or physiological damage. According to Safe Work Australia, mining was included in the top three industry sectors with compensation claims due to deafness. Within the mining industry, coal mining had the highest number and highest incidence rate, so the threat to hearing is very profound and in need of attention. Machine noise reduction strategies can help minimise health impacts on mine site workers.

Machinery noise regulations are set by governing bodies to ensure their operations do not disturb neighbours with excessive noise, particularly at night. Hunter Valley coal mine was fined $15,000 AUD for excessive noise at night by the NSW Environment Protection Authority (EPA). They exceeded their set noise levels by 3dB, causing production to halt during evenings to avoid fines and further development restrictions. Machine noise reduction strategies can assist with managing workers’ safety, and environmental and community expectations.

What is a truck-mounted attenuator?

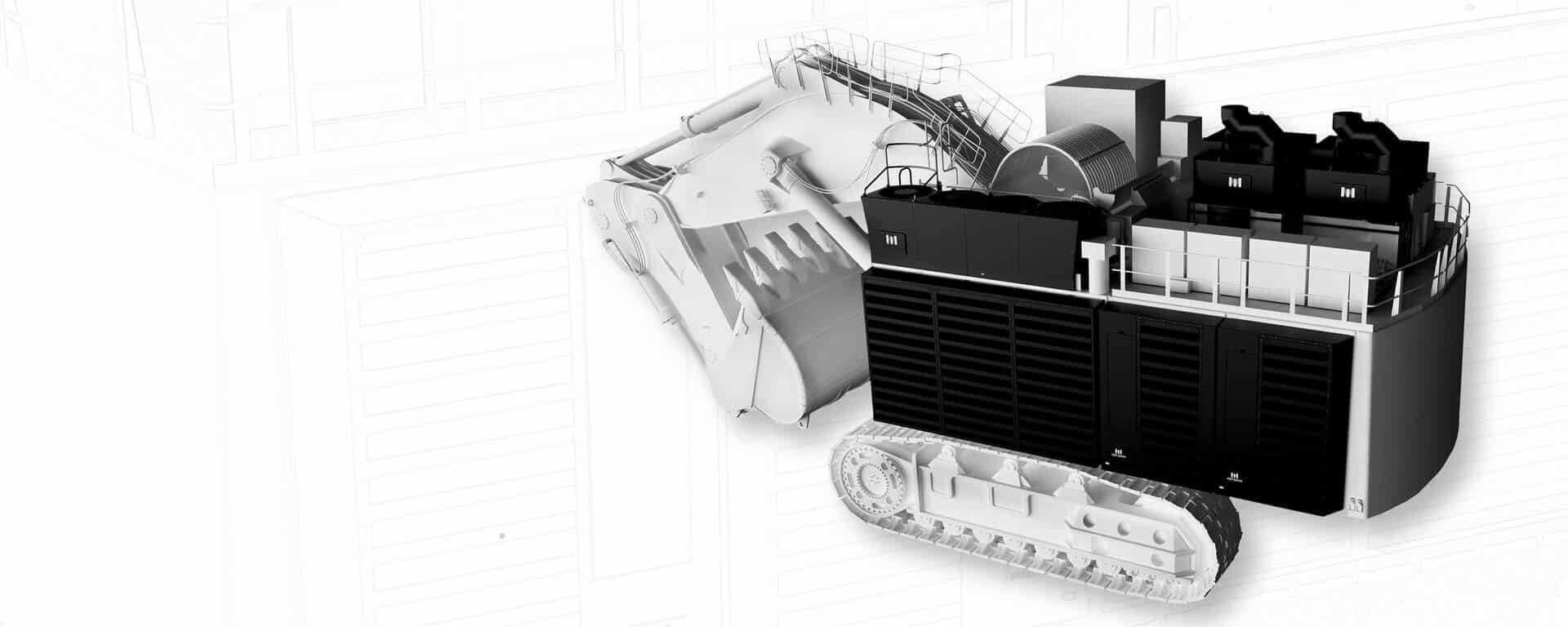

A truck-mounted attenuator is a device that is fitted to the exhaust of a machine in order to reduce machine noise levels. Truck-mounted attenuators are often used on open-cut mines where the increased noise levels can halt production or reduce mine operating hours.

Minetek’s sound attenuation packages provide clear benefits beyond sound reduction including prevention of overheating through engineered designs, ease of maintenance, less downtime, compliance with strict government regulators, reduction of fines, and improved community relations. Our engineered machine noise reduction solutions help to reduce noise by intelligently treating the noise sources in the most effective way, by treating noise from the source. Providing noise reduction solutions across mining fleets is expected to save operators considerable amounts of money in the process.

More than often, whilst treating the source of machinery noise, Minetek also lowers the risk of the vehicle overheating through increased airflow. Our maintenance plan allows operators to regularly maintain machines without having to remove the truck-mounted attenuator. Our turnkey sound attenuation solutions ensure the performance of the machine is not impacted by our sound reduction efforts. Minetek Sound provides clear maintenance guidelines, reducing the downtime of machinery and guaranteeing optimal machine performance.

Machine noise reduction strategies

Our solutions can help reduce machine noise on just about any large diesel machinery. Backed by our long history and proven track record of working with OEMs such as Hitachi, Liebherr, Komatsu, JCB and Caterpillar. Minetek’s machinery noise reduction packages include noise surveys and evaluation, safety advice for the operator, mine site inspections and site recommendations, in-cab testing and recommendations and Work Health and Safety noise recommendations.

The noise assessment process is extremely thorough, with the ability to accurately predict noise level reductions and guarantee accurate sound reduction levels in accordance with regulatory noise criteria. We have multiple case studies with a proven track record of hitting our noise reduction targets across all past projects.

Our rigorous testing involves checking the noise output when stationary and during in situ operating conditions. These include both uphill and downhill travel, whilst loaded and unloaded along with any applicable parameters as specified. To ensure 100% accuracy of our results, we provide our clients with a reputable independent noise report from a third party.