In the dynamic landscape of underground mining, where operational efficiency and safety are paramount, the need for robust and adaptable ventilation systems is crucial. As mines expand deeper and wider to meet growing production demands, secondary ventilation remains a critical element in maintaining safe and efficient operations. Minetek’s Raptor™ Secondary Series Fan builds on the proven approach of traditional secondary fans, offering a superior solution that is more powerful and compact. While utilizing the same fundamental methodology as existing systems, the Raptor delivers enhanced airflow, improved energy efficiency, and a smaller footprint, helping mining operations scale seamlessly while boosting both productivity and worker safety.

Understanding the Role of Secondary Ventilation in Mine Expansions

Secondary auxiliary fans and ventilation systems play a critical role in underground mining environments, particularly during expansions. These systems are typically deployed in development headings, stopes, and auxiliary areas where primary ventilation may not suffice. They ensure the delivery of fresh air to dilute harmful gases, remove dust, and maintain breathable conditions for workers. As mines expand, the demand for flexible, high-performance ventilation increases exponentially. Longer duct runs, tighter spaces in declines, and the need for compliant airflow become essential to sustain production targets without compromising safety.

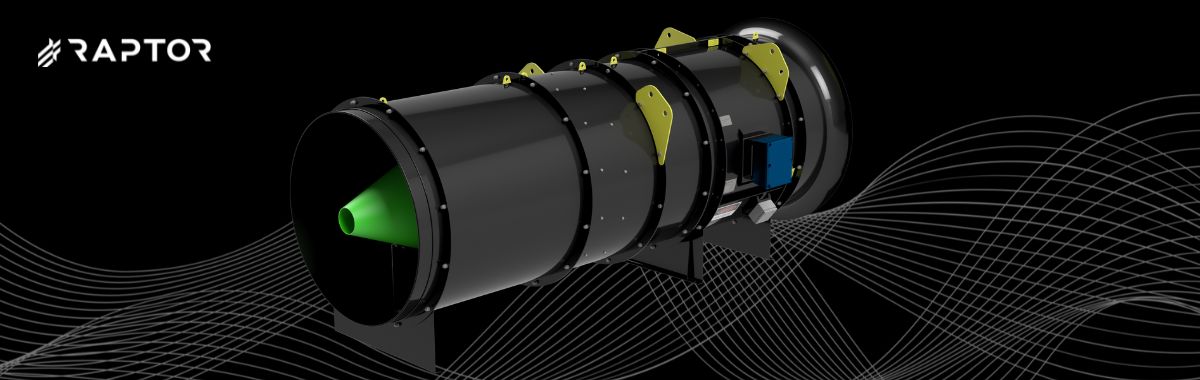

Minetek’s Raptor™ Secondary Series Fan is engineered precisely for these applications. Unlike conventional secondary fans, it provides high-pressure and high-flow capabilities, enabling extended duct runs while maintaining optimal ventilation compliance with minimal fans required. This makes it ideal for mines undergoing phased expansions, where new headings require rapid deployment of ventilation without halting operations.

Secondary Fan Key Features and Benefits

At the heart of the Raptor™ Secondary Series Fan is its single-stage motor design, which sets it apart from industry standards. This configuration absorbs significantly less power, requiring 50 kW less than the typical twin 110 kW fan, while delivering equivalent performance in airflow. The result is a more energy-efficient secondary ventilation system that reduces operational costs without sacrificing output.

One of the standout features is its compact and lightweight build. Measuring 2500 mm shorter and 1300 kg lighter than comparable twin-motor fans, the Raptor™ enhances installation efficiency. It can be lifted and installed as a single unit, eliminating the need for piecewise assembly that is common with heavier alternatives. This not only accelerates setup times but also minimizes risks associated with handling heavy equipment in confined underground spaces. For mines with limited access or steep declines, the smaller footprint allows installation in tighter areas, ensuring ventilation reaches even the most challenging zones.

These attributes further amplify safety and ease of relocation. The lighter design reduces strain on personnel and equipment during transport and repositioning, which is particularly beneficial in dynamic mining environments where ventilation needs shift frequently. Additionally, the fan’s aluminum impeller contributes to reliable, long-term performance under harsh conditions.

From a compliance perspective, the Raptor’s high-pressure and high-flow output supports longer duct extensions, ensuring that airflow meets or exceeds government standards. This directly translates to improved mine site efficiency, allowing operations to achieve production targets with fewer disruptions.

Addressing Common Challenges in Secondary Ventilation

Many mining operations adhere to familiar twin 110 kW fans as the default choice, often unaware of alternatives that could alleviate subtle inefficiencies. These include higher energy consumption, cumbersome installations, and the logistical burdens of multi-piece setups. Minetek’s Raptor™ Secondary Series Fan introduces a superior pathway by leveraging a single-stage architecture, which inherently makes the unit lighter and shorter, without the need for additional silencers or dual motors. Importantly, it achieves the same airflow as competitors, providing a direct upgrade for those seeking optimization.

Elevating Mine Safety and Efficiency with Minetek

Minetek is committed to raising the bar in mine ventilation through straightforward, reliable solutions, such as the Raptor™ Secondary Series Fan. By prioritizing energy efficiency, ease of use, and uncompromised performance, this secondary ventilation system not only supports current operations but also future-proofs expansions. Mining professionals can expect safer working conditions, reduced downtime, and cost savings that contribute to overall sustainability.

For mining operations seeking a more efficient secondary ventilation option, the Raptor™ represents a pivotal advancement. Contact Minetek today to learn how this scalable secondary ventilation solution can transform your site.