In the early days, systems were rudimentary, relying on natural airflow or simple fans. As mines grew deeper and regulations tightened, ventilation systems became more sophisticated. By the mid-20th century, electric fans were standard, but many were inefficient, oversized, and operated continuously, significantly inflating energy usage.

The turning point: Sustainability and efficiency take the lead

As energy costs surged in the 21st century, the mining industry faced a critical turning point. At the same time, ESG pressures mounted—PwC’s 2023 Mine Report revealed 35% of mining CEOs now rank climate risks among their top concerns. This convergence of environmental and economic demands ignited a wave of innovation. Minetek Air responded with underground ventilation solutions that go beyond simply moving air—they optimise it. Today, technologies like VoD and high-output axial fans are reshaping industry standards, proving that performance and sustainability can thrive together underground.

This convergence of environmental and economic pressure sparked a new wave of innovation. Minetek Air responded by engineering smart ventilation solutions designed not just to move air, but to optimise it.

Technologies like VoD and high-output axial fans are now transforming how ventilation is managed, proving that performance and sustainability can thrive together underground.

Minetek Air’s four pillars of impact

1. Energy-efficient mining solutions: Cutting costs at the core

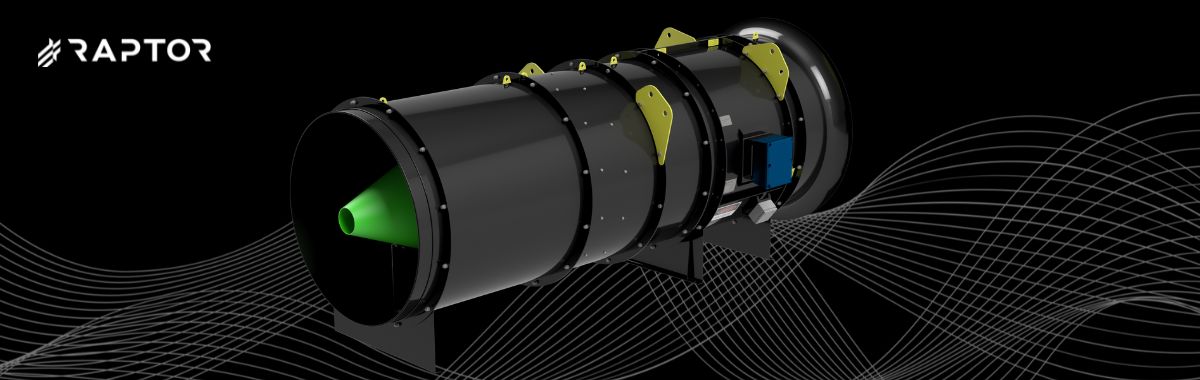

Mining energy consumption is a beast, but Minetek tames it with precision. Traditional ventilation systems run at full tilt 24/7, wasting power in areas where no one’s working. Minetek energy-efficient mining solutions flip that script. Our high output axial fans, paired with the Mine Air Control (MAC) system, deliver airflow only when and where it’s needed, slashing power usage by up to 50%. A 2024 Straits Research report projects the mine ventilation market to hit $1.86 billion by 2032, driven by demand for such technologies. For a typical underground mine, where ventilation eats up nearly half the energy budget, this translates to millions in savings annually – money that can be reinvested into operations or ESG initiatives. It’s not just cost-cutting; it’s strategic resource management.

2. Ventilation on Demand (VoD): Smart airflow, smarter savings

Ventilation on Demand (VoD) is the brain behind Minetek Air’s brawn. Integrated with mine communication systems, VoD uses RFID trackers to monitor worker and vehicle locations, adjusting airflow in real time. No more blasting air into idle tunnels – Minetek’s systems sync with schedules and activity, reducing energy waste. The Canadian Mining Journal reported in 2023 that VoD can cut energy intensity by 20-50%, with payback periods as short as two years. At a Gold Mine in Western Australia, Minetek’s VoD-enabled primary fans (1,100kW, 280-350 m³/sec) met production needs while slashing power costs. This isn’t just about efficiency; it’s about giving mine managers control to optimise underground mine ventilation without compromising safety or output.